The UK-based clean technology company Altilium has announced that construction of the UK’s first at-scale electric vehicle (EV) battery recycling and refining plant has started in Plymouth.

The company claims the plant will have the capacity to recover critical minerals from 24,000 EVs a year.

This includes lithium, nickel and graphite.

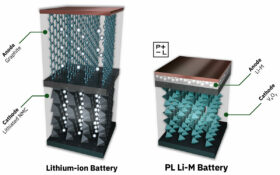

Battery scrap will be recycled using the firm’s proprietary process, which is said to create mixed hydroxide precipitate (MHP) and lithium sulphate.

It said these are critical intermediate materials for the domestic production of battery cathodes.

The plant, which will be on a 4-acre site, will support sustainable battery materials production, it said.

Now, the UK is mostly dependant on the importing of critical battery production supply.

But the UK is expected to need up to 40% of current global lithium production and up 30% of current global graphite production by 2030, according to the UK Critical Minerals Intelligence Centre (CMIC).

The firm believes that battery recycling so far as been focused on shredding batteries and black mass production.

But valuable battery metals like lithium and nickel are needed in the UK through advanced hydrometallurgical refining.

Dr Christian Marston, Altilium COO, said: “Our ACT 3 site marks the next phase in Altilium’s mission to close the loop on battery materials here in Britain. We are proud to be building this scale-up facility here in Plymouth, which will be a cornerstone of the UK’s EV battery supply chain. This is about taking a strategic and incremental approach to scaling a vital new industry, one that ensures value stays in the country and creates long-term skilled green jobs.”

Image: Altilium’s factory has started being constructed. Credit: Altilium.