LG Energy Solution and Derichebourg JV to create a European closed-loop system for lithium-ion batteries

Battery giant LG Energy Solution and metal recycler Derichebourg are set to form a joint venture that will develop a circular economy for lithium-ion battery materials in Europe.

The companies are scheduled to begin building a pre-processing facility that will discharge, dismantle and shred batteries in Bruyères-sur-Oise, northern France next year.

The facility will extract black mass from battery waste generated during battery production, and from end-of-life EV batteries. The black mass will then undergo further post-processing to recover materials such as lithium, nickel, and cobalt. Those materials will then be used in LG Energy Solution’s battery production.

The plant is due to be commissioned in 2027 and will have a processing capacity of more than 20,000 tons per year at full operation, say the firms.

Under the agreement, South Korean firm LG Energy Solution will supply battery scrap from its facility in Poland. Meanwhile, French-firm Derichebourg will provide end-of-life EV batteries collected from France and surrounding countries.

EU Battery Regulation mandates that from 2031 a minimum level of recycled content must be used in batteries sold in Europe.

This JV will address that mandate by supporting vehicle OEMs to establish a closed-loop battery recycling system that further promotes a circular economy.

The partnership will be LG Energy Solution’s first battery recycling joint venture in Europe.

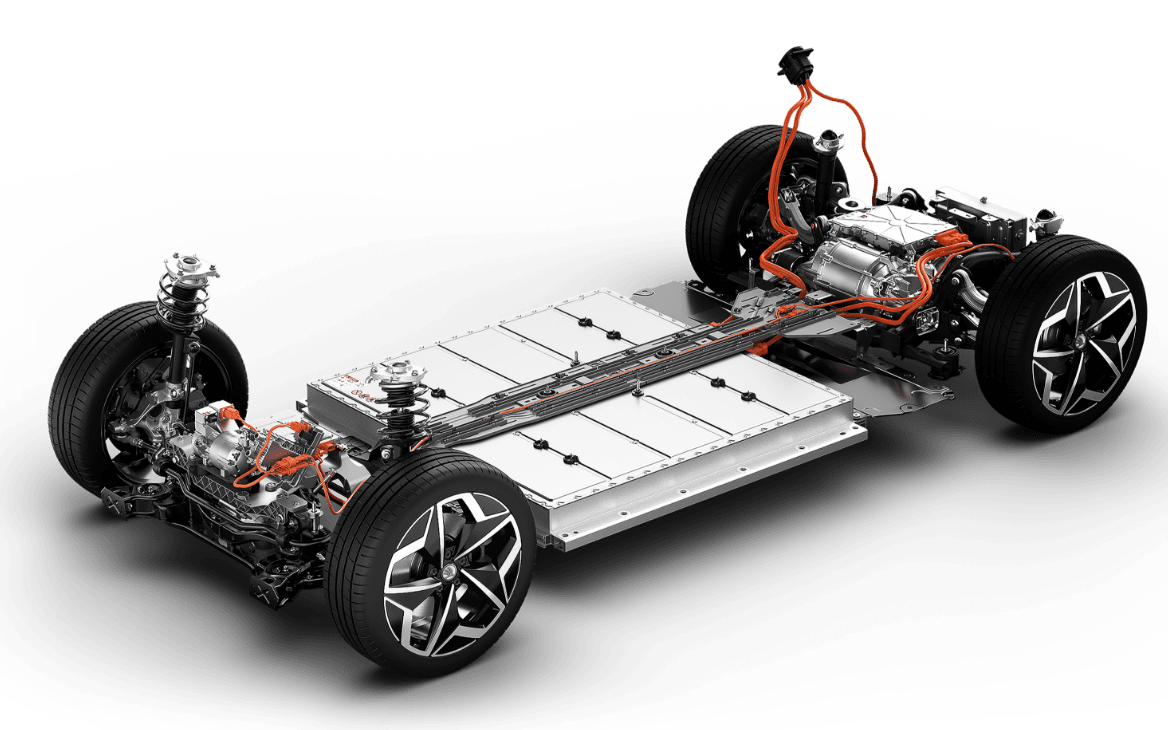

Picture: LG Energy Solution