Pasidu Pallawela, director of Edinburgh-based energy storage solution provider StorTera, explores the impact of energy storage systems and asks: Can batteries enable a truly sustainable future?

Why should batteries be sustainable? The big picture

Energy storage systems are being employed to support an increasingly diverse range of applications, from megawatt-scale grid storage systems to microelectronic systems. In an era where humanity is fighting the climate crisis, energy storage is seen as one of the key enabling technologies to support the decarbonisation of modern energy systems. This fact, coupled with the increasing uptake of electric vehicles (EVs), which use significant volumes of batteries, means that battery manufacturing is expected to consume enormous amounts of the earth’s natural resources.

One valid question is, how can batteries become a sustainable technology for the future? In a nutshell, if an energy storage system has low embedded carbon levels, low impact on natural eco-systems during its production, lower levelised cost of storage and if the energy storage system can be recycled or reused at the end of life, it can be argued that such an energy storage system is sustainable.

However, the true sustainability of an energy storage system cannot be quantified or compared accurately without having suitable sustainability metrics identified. This article considers the important metrics to measure the sustainability of battery technologies and the features necessary for truly sustainable battery systems.

Where have things gone wrong?

I’m celebrating my 20th year in the renewable energy industry this year and a colleague I’ve known throughout my entire career, who is a senior engineer in the telecoms industry, stated that a particular battery type (say battery chemistry B) with a carbon footprint of 52 eq CO2 kg/kWh is more sustainable than lithium-ion batteries which have a carbon footprint of 70 eq CO2 kg/kWh. On the first observation, that sounds correct. On reflection, however, I looked at the number of cycles each battery can perform before the end of life; battery B can only be used for 500 cycles, whereas lithium-ion could manage nearly 2,000 cycles under the same conditions in a telecom tower installation.

As a consequence, battery B would have to be replaced four times in order to meet the equivalent cycle life of lithium-ion batteries. Therefore, the real carbon footprint of battery B is actually four times higher than its quoted carbon footprint. While lithium-ion has 70 eq CO2 kg/kWh, battery B now has a carbon footprint of 208 eq CO2 kg/kWh, if it is used for 2,000 cycles. This simple example highlights the fact that sustainability metrics such as carbon footprint should be levelised for the number of cycles that it can perform before its end of life.

This is just the tip of the iceberg, as the carbon footprint is just one factor from a sustainability point of view. Stakeholders in the renewable energy industry such as policymakers, investors, developers, and consultants are not fully informed as it is extremely difficult to find reliable and accurate information about battery sustainability.

The present metrics used to measure the sustainability of batteries are misleading. Therefore, accurate and reliable metrics are needed.

Correct battery sustainability measurements are important

The battery industry is growing fast with many stakeholders engaging at an accelerated pace. There are business leaders, policymakers, government bodies, and many investment firms pledging more investment and resources into developing sustainable battery technologies for the future. But how can these stakeholders know which battery technology is sustainable when the techniques to compare the sustainability of batteries do not consider the full picture? Or, what if the present measurement techniques and sustainability metrics used to compare the sustainability of battery technologies are not accurate? For this reason, it is important that correct and well analysed metrics be openly available.

The most effective battery sustainability metrics

There are many sustainability metrics that can be used and it is important to adapt different metrics to measure different products and services to fully understand and compare their environmental impact. Below are some of the most important quantitative metrics which are most applicable to battery storage technologies. As shown, it is essential that these metrics are levelised for the number of cycles that the particular battery technology can perform before end of life. The metrics selected to be discussed in this article are:

- Levelised carbon emissions (LCE)

- Levelised water footprint (LWFP)

- Levelised ecological footprint (LEFP)

- Levelised cost of storage (LCOS)

- Percentage recyclability at end of life

If an industrial battery technology has low values of LCE, LWFP, LEFP, and LCOS and a high percentage of recyclability at end of life, then this would truly be a sustainable battery. First, we need to understand what these sustainability metrics mean.

Levelised carbon emissions

Among the most commonly used battery types are lithium-ion batteries, which have a carbon footprint of around 70kg of eq CO2/kWh (Ishihara, 2020). This is an important metric, but not a comprehensive sustainability indicator.

The true lifecycle carbon emissions of batteries, or the levelised CO2 emissions of a battery, are given by the LCE. This is a measure of greenhouse gases (GHGs) emitted per kWh stored and released using the battery with units of this metric in eq CO2 g/kWh/cycle. Rather than just estimating how much GHG is emitted while manufacturing a kWh of a battery, this determines the concentration of GHGs attributable to each kWh stored in the battery, providing a true and comparable sustainability metric. Battery technologies with low carbon footprints and long cycle lives will have low LCE values.

Levelised water footprint

Another important metric is the levelised water footprint, i.e. the mass of water needed to generate each of the products and services. For batteries, this is measured in tonnes of water/kWh/cycle to determine the amount of water used per kWh stored and released in the battery during its lifetime.

Water is becoming an increasingly scarce resource and the use of water is related to water pollution and damage to aquatic life. If the battery technology has a longer cycle life then each tonne of water used can support more kWhs of stored renewable energy. The metric further improves if the battery technology uses less water during its production and operation.

Levelised ecological footprint

The ecological footprint measures the demand or damage on a natural ecosystem to supply the resources required to produce a product or a service. The ecological footprint is measured using global square metres (m2), global square decimetre (dm2), or global hectares. The levelised ecological footprint applicable for batteries is measured in global dm2/kWh/cycle.

In other words, this is a measure of the ecological damage the battery causes per kWh stored and released by the battery. This metric looks at the total ecological damage done during any form of manufacturing of a product or a service.

Levelised cost of storage

The levelised cost of storage is the cost of storing and subsequently retrieving a MWh of energy from a battery technology. This is measured in £/MWh. LCOS isn’t a sustainability metric in itself, but it is indirectly connected. If the LCOS of a battery technology is lower than a particular threshold, it would enable rapid decarbonisation, leading the way to a sustainable future.

A recent report published by the US Energy Information Administration indicated that the levelised cost of energy [(LCOE) – all-inclusive cost to produce a MWh of energy using various generation sources] for natural gas combined cycle and standalone solar PV will be $47.40/MWh and $38.77/MWh respectively by 2024 (US energy administration, 2022).

Therefore, a battery technology with a LCOS of less than $8.63/MWh by 2024 can make on-demand renewable energy (energy generated by solar PV and stored in a battery to be dispatched any time when required similar to a fossil fuel generator) more economical than the cheapest fossil fuel-generated energy. This could unlock the potential of renewable energy, enabling its widespread use.

A more sustainable future must rely on the use of clean energy and so batteries with a low LCOS are important for benchmarking the technology.

Percentage recyclability at end of life

With the increasing uptake of Evs, coupled with numerous other battery applications, it’s no surprise that mountains of used batteries are expected to be accumulated for recycling. According to data published by London-based storage recycling research group Circular Energy Storage, more than 1.2 million tonnes of lithium-ion batteries will reach their end of life yearly by 2030. While lithium-ion batteries can be recycled, if existing practices for managing used batteries continue, recycling all end-of-life batteries swiftly will be a challenging task. Current battery recycling techniques are also highly water- and energy-intensive processes.

According to Naomi J. Boxall, an environmental scientist at Australia’s Commonwealth Scientific and Industrial Research Organisation, barely 2-3% of lithium-ion batteries are collected and transported abroad for recycling in Australia. Similarly, the lithium-ion battery recycling rate in the US is around 1% (Yanamandra, et al 2022).

It is essential for batteries to become fully recyclable or reusable at the end of life. Reusing material at the end of life from a battery is far more beneficial than recycling, which, depending on the process, can be energy intensive in itself. Lead-acid batteries, for example, can be easily recycled, with 99% rates being achieved. However, only lead can be fully recovered (Yanamandra et al, 2022).

Novel battery technologies such as StorTera’s single-liquid flow battery (SLIQ) are made with reuse and recycling at the core of their design philosophy. The bulk of the battery comprises the liquid catholyte, tank, and power stack, all of which can be fully reused at end of life. The cell bodies can be recycled easily, as everything, including the cells and connectors, is manufactured using a single plastic.

Comparing sustainability metrics

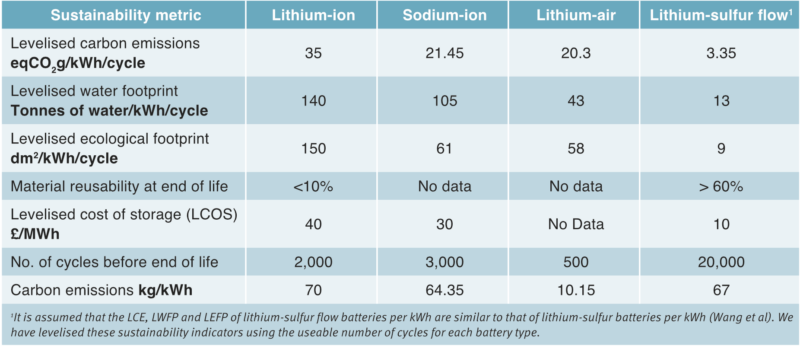

Table 1 summarises the key sustainability metrics for four different battery types.

Multiple battery chemistries will be needed to satisfy the electrification requirements of various sectors of the economy. Understanding different battery chemistries’ sustainability credentials will be one important factor in making technology decisions. The top rows of the table compare the LCE, LWFP, and LEFP for four different battery technologies (Wang et al 2020).

Battery technologies such as lithium-ion, lithium-sulfur flow batteries, and sodium-ion have similar levels of carbon emissions but, when the levelised emissions are calculated, battery technologies with long cycle lives – such as the lithium-sulfur flow battery – perform better in terms of sustainability compared to other battery technologies.

Lithium-sulfur flow battery technology is safe, has a low initial capital cost, has a high energy density compared to other flow batteries, and is durable. Therefore, this technology can be used for stationary energy storage systems, heavy goods vehicles, and for the electrification of inland shipping vessels.

Some experts argue that novel battery technologies such as sodium-ion are sustainable due to the fact that they do not use lithium. However, sodium-ion battery technology has a comparatively higher ecological footprint and a higher water footprint (Huang, Hu, 2020) compared to the other novel battery technologies listed in the table. Therefore, on this metric, it is not as sustainable a battery technology as some others. This is a good example of how correct metrics can be used effectively to compare the sustainability of different battery technologies.

Is a sustainability index for batteries the answer?

Batteries do not come without a cost to the environment, despite their key role in increasing the integration of renewable energy sources into our economies and in decarbonising the transportation sector. Battery production and disposal have an impact on biodiversity as well as water and air quality, from mining and extraction of critical raw materials to their disposal and recycling, not to mention a potentially significant carbon footprint if inefficient manufacturing processes and carbon-intensive energy sources are used.

Therefore, it is crucial that key stakeholders such as governments, policymakers, green investors, and environmentally conscious customers clearly understand how sustainability measures should be applied to battery technologies.

One good example is the European Commission’s proposal, adopted in December 2020, for the regulation of batteries and waste batteries. This was the first policy worldwide to cover the whole battery value chain, a significant step forward toward a sustainable future.

In one of the documents published, they mention that these regulations were imposed to put a truly sustainable European battery value chain in place (Enhancing sustainability of batteries, 2021). Although the first of its kind, unfortunately, this regulation does not address important metrics such as LCE, LWFP, LEFP, and LCOS, meaning the effectiveness of the regulation must be questioned.

The European Union has implemented a genuinely important requirement but has fallen short of delivering a truly sustainable policy. This is why it is so important that policymakers and key stakeholders in the battery industry start to debate and discuss how to identify the correct metrics for the sustainability of measuring future battery technologies.

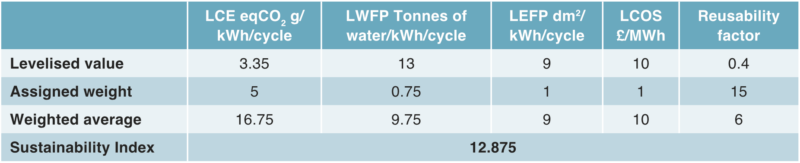

As a final remark, I would argue that the battery industry should formulate a Sustainability Index by assigning suitable weights to each metric and then calculating a weighted average to arrive at the final value to compare different battery technologies.

An example is provided in Table 2, which shows the sustainability index calculation for lithium-sulfur flow batteries, using imaginary weights for each levelised metric. These metrics are not accurate and have to be agreed upon after a wider discussion.

An industry-wide dialogue should be initiated to identify the correct units and weights for each sustainability metric, depending on their relative importance. This will give key stakeholders in the battery industry the ability to easily and accurately compare the sustainability of different battery technologies in the future.