John Miller explains how new carbon improvements are allowing supercaps to invade the space of conventional devices— which will have profound effects on performance and price.

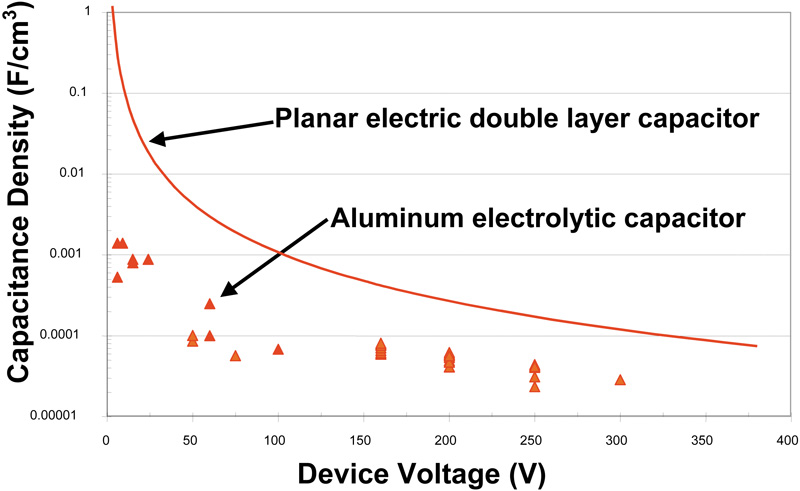

The autumn 2010 issue of BEST reported on the development of an electric double layer capacitor (sometimes referred to by the product names "Supercapacitor" and "Ultracapacitor") with an ability to filter AC power and thereby function like a conventional aluminium electrolytic capacitor. The particular capacitor referred to in that article was a developmental device having vertically-oriented graphene nanosheet electrodes with a very special structure. Though fairly novel at the time, activity has since . . .

to continue reading this article...

Sign up to any Premium subscription to continue reading

To read this article, and get access to all the Premium content on bestmag.co.uk, sign up for a Premium subscription.

view subscription optionsAlready Subscribed? Log In