Editor Gerry Woolf talks to Brian Morin about how his new research consortium will create safer lithium-ion batteries.

It’s a few years since Brian Morin appeared at the late Shep Wolsky’s famous Florida battery seminar, announcing a novel lithium-ion battery separator— one that would not shrink in the event of a thermal runaway. A separator that would help prevent battery fires and which would seriously improve the safety record of lithium-ion batteries.

Morin has little doubt that he has gone a long way to inventing a better mousetrap. But while customers have beaten a path to his door for development activities, actual adoptions have been few and very slow. “Big Asian customers don’t want to risk years of development on the availability of materials from a start-up in South Carolina, using contract manufacturing in Germany with very long lead times,” he told me. Mobile phones continue to burn and development work is still high.

Lithium-ion battery safety

BEST magazine’s interest in lithium-ion battery fires goes back to at least 2007, when Dr Brian Barnett of Tiax revealed the dendritic short theory behind lithium-ion thermal runaways. And the growth of consumer electronics and electric vehicles powered by lithium-ion has sky rocketed.

While the theory is accepted, there is no technology to warn of the potential fires. The US Federal Aviation Authority has said that in 2018 there was a battery related incident every 10 days. This has led to modification and ever-increasing tightening on what can and can’t be carried in aircraft luggage, in carry-on bags and an outright ban on battery freight in passenger planes.

The plain hard truth is that the separator’s failure is at the very root of lithium battery fires. Morin’s original Dreamweaver separator was certainly part of the solution.

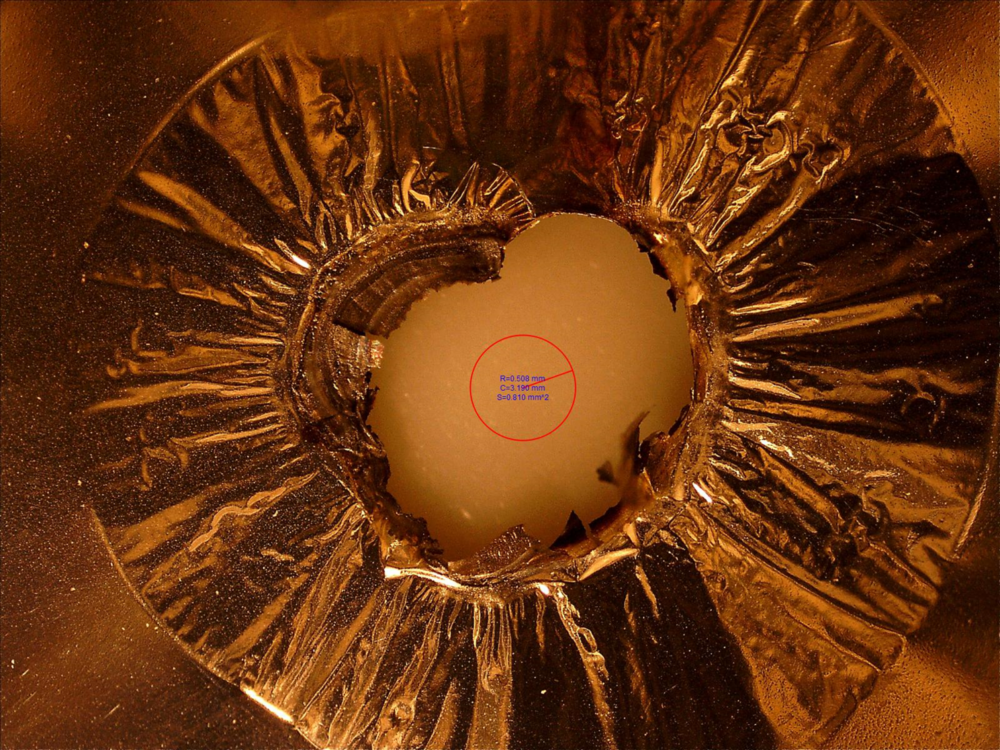

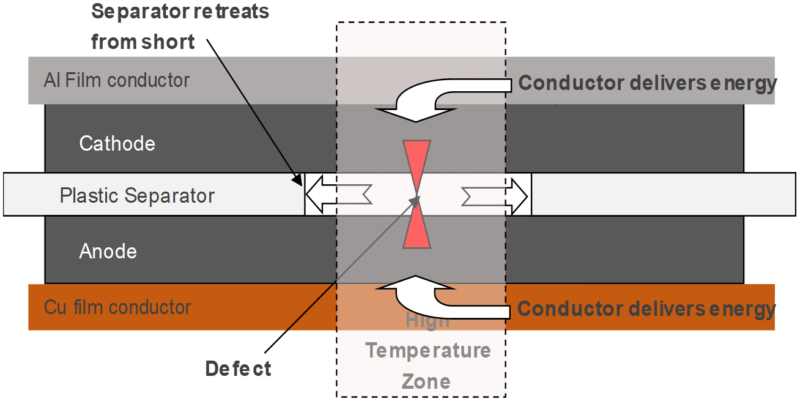

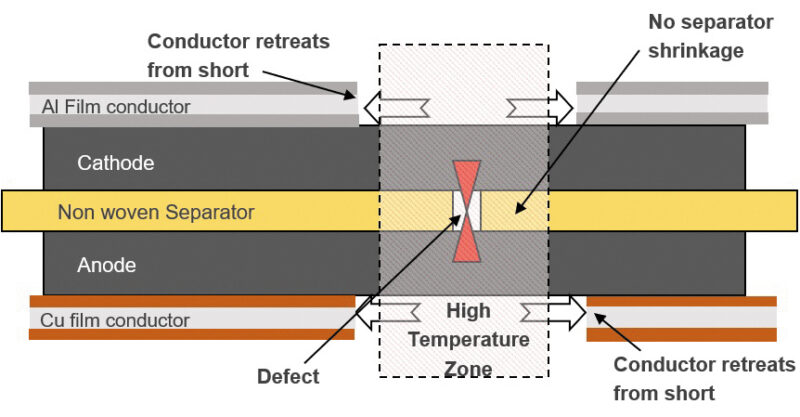

Technically, making the separator stop shrinking is only half of the solution— it can keep a short from getting worse, but doesn’t flip the switch. To do that, the current needs to be shut off, like a fuse. His new company, Soteria Battery Innovation Group, does this by making the current collector unstable, so that in the event of a short, it stops functioning, acting like an internal fuse. The picture shows a current collector that has burned out around a short. It just disappears, isolating the short, and only takes a few microseconds to activate, unlike ‘shutdown’ separators, which wait for the whole cell to heat up.

Perhaps the most challenging task in battery safety is to reduce the probability for the formation of internal short circuits— and if they cannot be avoided to handle such incidents in a more controlled way. In case particles or dendrites penetrate the separator and lead to a current flow, the surrounding of the short will heat up due to Joule heating. At this stage, the separator must not shrink to avoid exposure of both electrodes to each other. Last but not least the separator must not melt, even if larger currents are flowing and the temperature is rising to a few hundred degrees centigrade.

With almost all of today’s lithium-ion batteries made with polyolefin separators, which shrink and fail at the high temperatures associated with dendritic shorts, separator failure leads to thermal runaway and fires.

A string of companies including Morin’s Dreamweaver and big names have been developing ‘third generation’ thermally stable separators— big names like DuPont, Freudenberg, Gore-Tex, Leclanché, Mitsubishi Paper and Evonik (now owned by Electrovaya).

A safety solution

So is it possible for a small company like Dreamweaver to compete with the big guys? Morin believes it is, but you need a different business model and the full architecture including the stable separator and current collector with a fuse.

That business model is called the Soteria Battery Innovation Group, or Soteria BIG for short. Rather than ‘tout your wares’ to any number of lithium-ion battery makers, Morin has a new approach— well, new to the battery industry— but not unknown in the world of electronics says Morin— think about Bluetooth. We all use it.

Bluetooth is a low cost, low power, short-range group of radio technologies which got rid of so many cables associated with your digital devices like phones,

Ericsson Mobile Communications developed it in 1994, but the technology was valuable to so many companies in the electronics world that it set up the Bluetooth Special Interest Group. The Bluetooth SIG is responsible for the further development of the Bluetooth standard. Sony Ericsson, Intel, IBM, Toshiba, Nokia, Microsoft and Motorola are some of the companies involved in the SIG. The composition of the Bluetooth SIG is one of the major strength of the Bluetooth technology. The mixture of both software and hardware suppliers participating in the further development of the Bluetooth technology ensures that Bluetooth products are made available to customers.

But a key driver to all this is ‘thin metal’— a fraction of a micron of metal on a thin polymer film. Reduce the thickness of copper and aluminium and not only have you saved weight and cost, but you’ve also produced a conductor not too different from an electrical fuse— a material which will fail when too high a current is passed through it. Present generation current collectors are more than capable of passing massive amperage which feeds energy into thermal runaway.

Potential licensees include players already operating in the food sector, who use thin metalised materials for packaging but would be new entrants into the battery world, or advanced material suppliers who want to expand their portfolio in the lithium-ion battery market.

Setting standards

One thing Soteria BIG will do is set standards— safety standards so aggressive that no lithium battery made today would pass. And only cells that pass will get to use the Soteria mark. Morin believes this will get the industry moving.

And the fire hazard is not going away. This spring, Amazon recalled 260,000 power banks for fire hazard. The company received more than 50 reports of the power banks overheating in the US, causing chemical burns and property damage. Soteria’s membership can only grow.