A US team from the Washington University in St. Louis has developed a stable sodium-ion coin cell that could one day replace lithium-ion batteries.

The ‘cheaper and smaller’ technology uses a thin layer of copper foil on the anode side of the battery as the current collector.

Taking into account only the active materials, the energy density of the tested coin cells were in the range of 310-340 Wh/kg.

For the 100 cycles, the team tested at 2C-rate and 3C-rate with the cells showing a >99.9% capacity retention rate per cycle, which projects the cells can run for more than 200 cycles before reaching 80% of the initial capacity.

The technology is ready for commercial tests and optimisation, say the team.

In the anode-free battery the ions are transformed into a metal where they plate themselves onto the copper foil, before dissolving when returning to the cathode.

The research was published 3 May in the journal Advanced Science.

Previously, anode-free batteries were unstable, and grew dendrites that were attributed to the reactivity of the alkali metals involved, namely sodium.

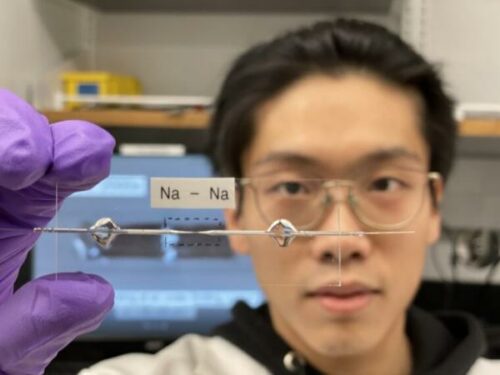

The technology was made in the laboratory of Peng Bai, assistant professor in the university’s Department of Energy, Environmental & Chemical Engineering in the McKelvey School of Engineering.

Bai told BEST: “Our focus here was the anode, which by itself (in a control cell) can run for more than 7,000 hours without degradation.

“But we need a better cathode to make the anode-free full cell to achieve longer cycle life.

“Once the optimised cathode material, either from us or from another research group or company, is identified the technology will be ready for commercialisation. It doesn’t require any special facilities other than what people currently use for lithium-ion batteries.”

He added: “Our demonstration shows that in terms of energy density it is comparable to lithium-ion batteries. So wherever people want to lower the cost of their lithium-ion batteries, they can use this anode-free sodium battery. They would not notice performance differences, but save a lot of money.”

The cost-saving for manufacturing the anode-free sodium (Na) battery comes from three aspects: the anode material (no need for anode materials like graphite); anode processing (no need to fabricate the graphite anode laminate); and the cathode material (Na-based materials are cheaper than lithium-based materials for synthesizing the cathode).

The concept of replacing lithium with sodium and removing the anode isn’t new, but the problem has been developing an anode-free battery with a reasonable lifetime, said Bai.

Bingyuan Ma, the paper’s first author and a doctoral student in Bai’s laboratory, said: “In our discovery, there are no dendrites; the deposit is smooth, with a metal luster.

“This kind of growth mode has never been observed for this kind of alkali metal.”

Watching the battery in action, the researchers saw shiny, smooth deposits of sodium, which eliminates morphological irregularities that can lead to the growth of dendrites.

Image: Bingyuan Ma holding a transparent capillary cell. Bai’s Lab at the McKelvey School of Engineering is the only one in the world with such diagnostic cells. (Courtesy: Bai Lab)