Solid-state lithium metal batteries are considered a promising next-generation technology due to their potential for improved safety and energy performance. One major reason for the optimism is the theoretical energy density, which has been assumed to be considerably higher than for conventional batteries.

A recent study published in Energy Storage Materials by researchers from Tohoku University, Shanghai Jiao Tong University, MIT, UW Madison, Johns Hopkins University, and St Andrews University, challenges some of the assumptions regarding energy efficiency.

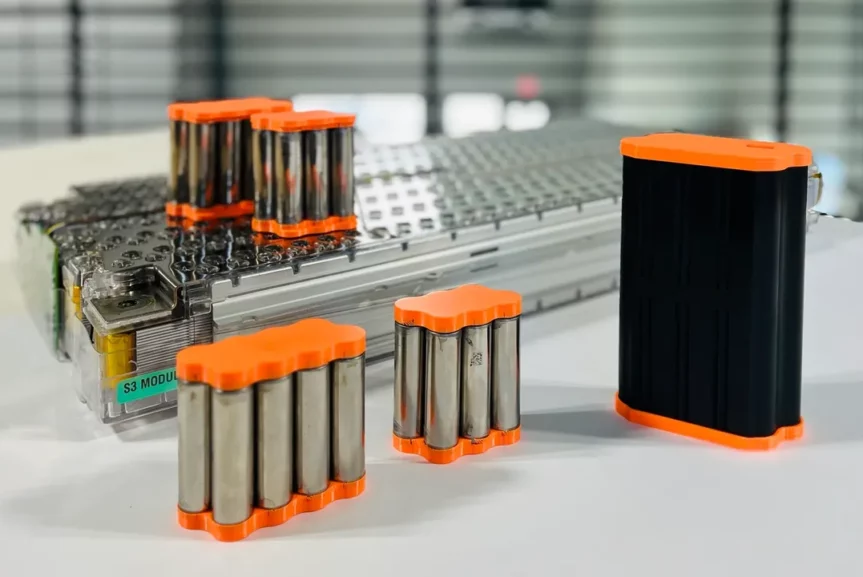

Detailed modelling of a practical LLZO-based pouch cell has revealed that this material does not significantly boost energy density. The study finds that even with an ultrathin 25 μm LLZO ceramic separator and a high-capacity cathode, the battery’s performance remains only slightly ahead of the best conventional lithium-ion cells.

The research reveals that an all-solid-state lithium metal battery (ASSLMB) using lithium lanthanum zirconium oxide (LLZO) would achieve a gravimetric energy density of only 272 Wh/kg, a marginal increase over the 250-270 Wh/kg offered by current lithium-ion batteries. Given the high production costs and manufacturing challenges associated with LLZO, the findings suggest that composite or quasi-solid-state electrolytes may be more viable alternatives.

“All-solid-state lithium metal batteries have been viewed as the future of energy storage, but our study shows that LLZO-based designs may not provide the expected leap in energy density,” said Eric Jianfeng Cheng, lead author of the study and researcher at WPI-AIMR, Tohoku University. “Even under ideal conditions, the gains are limited. LLZO is an excellent material from a stability standpoint, but its mechanical limitations and weight penalty create serious barriers to commercialization,” Cheng explained.

“Instead of focusing on a fully ceramic solid-state battery, we need to rethink our approach,” said Cheng. “By combining LLZO with polymer or gel-based electrolytes, we can improve manufacturability, reduce weight, and still maintain high performance.