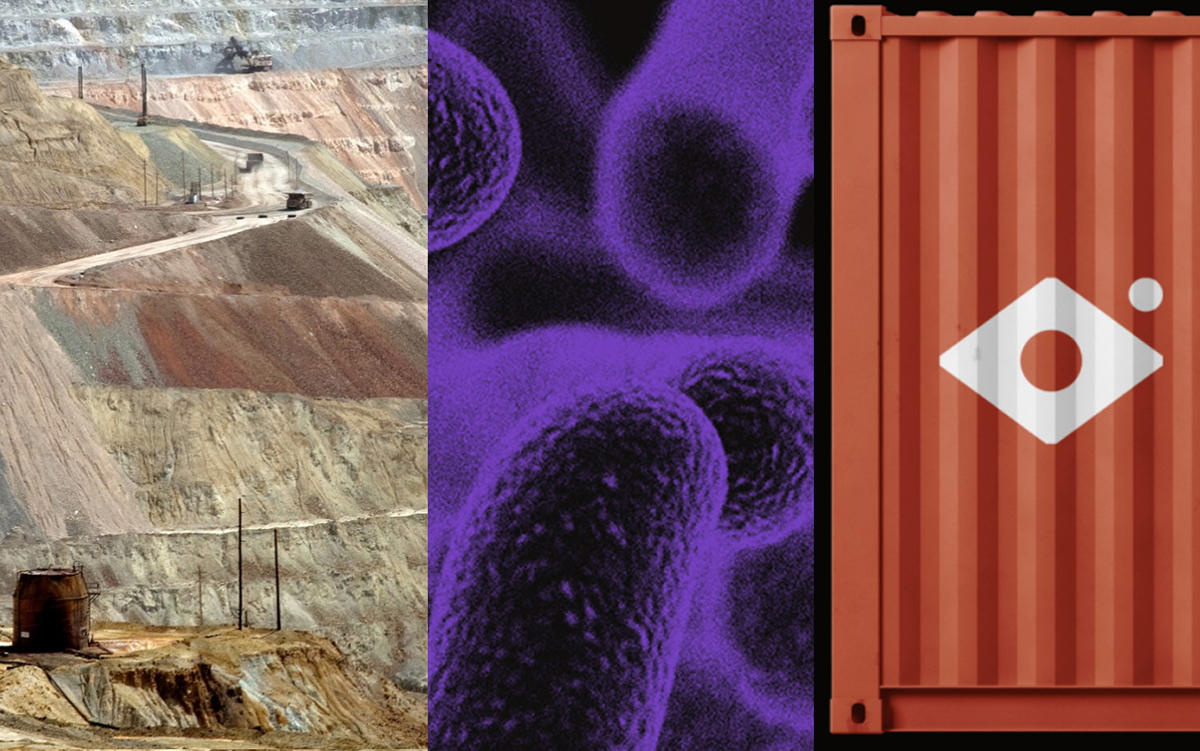

Battery materials firm Endolith has reported it’s bioleaching mining showed a “significant uplift” over conventional methods when extracting copper from low-grade ores.

The company said recent tests showed its biohydrometallurgy platform ‘increased’ copper recovery from sulfide ores with less than 1% chalcopyrite and pyrite.

Endolith uses microbes to facilitate the leaching process and AI-optimised monitoring to boost material recovery.

Tested under simulated field conditions, the company said its microbes outperformed conventional approaches to low-grade heap leaching.

Column tests were conducted using site-matched ore and fluids at temperatures ranging from 30°C to 65°C. Endolith reported its approach delivered faster and more complete copper recovery in each test.

Although the US company didn’t release numbers, its believed the technique could pave the way to extracting copper from mineralised waste previously considered uneconomical to process.

This could have an important impact because it’s believed as much as 70% of copper reserves are contained in low-grade or hard-to-process ores. This materials source would help meet global copper demand, which is expected to reach 50 million metric tonnes annually by 2035.

The testing used samples from Think & Act Differently (TAD), the innovation arm of mining firm BHP.

Liz Dennett, CEO of Endolith, said: “Working with the support from the TAD program, we’ve proven a solution that unlocks vast copper resources in a scalable, low-impact manner, one that helps secure critical mineral supply chains for decades to come.”