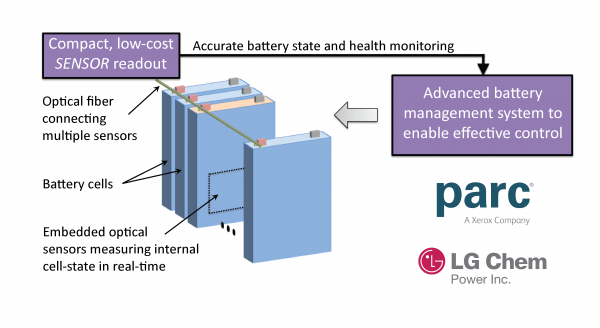

A fibre-optic sensing battery management system has been tested by Xerox company PARC and LG Chem to focus initially on hybrid and electric vehicles (HEVs).

The Sensor system by PARC uses compact wave-length detection technology alongside its machine-learning and network knowhow to measure cell state and predict remaining life.

Testing has shown positive results with li-ion batteries at cell and module levels, demonstrating 2.5% or better SoX accuracy across various use cases, said Ajay Raghavan, PARC Research Area Manager and Principal Investigator.

The partnership is being funded under the US Department of Energy‘s Advanced Research Projects Agency-Energy (ARPA-E) within the Advanced Management and Protection of Energy Storage Devices (AMPED) program.

LG Chem has also signed up to support a PV-testing facility in Georgia.

US utility group Southern Company and the Electric Power Research Institute (EPRI) commissioned a 1 MW/2 megawatt-hour battery energy system where LG Chem supplied the batteries and power conversion equipment and oversaw battery installation.

The South Korean chemical giant has been busy. It is said to have sold one of its separator-manufacturing plants to Japanese chemical firm Toray Industries.

Toray will buy LG Chem’s safety separator plant in Ochang for an estimated US$25 million, structuring it as a wholly-owned subsidiary. It will be Toray’s third separator plant, with the other two both in central South Korea.

Toray plans to supply the output mainly to LG Chem. The Ochang site will be the third separator plant for Toray, after the one in Tochigi Prefecture and another in Gumi, also in central South Korea.

LG Chem and Japan’s Panasonic control about 70% of the global automotive lithium-ion battery market.