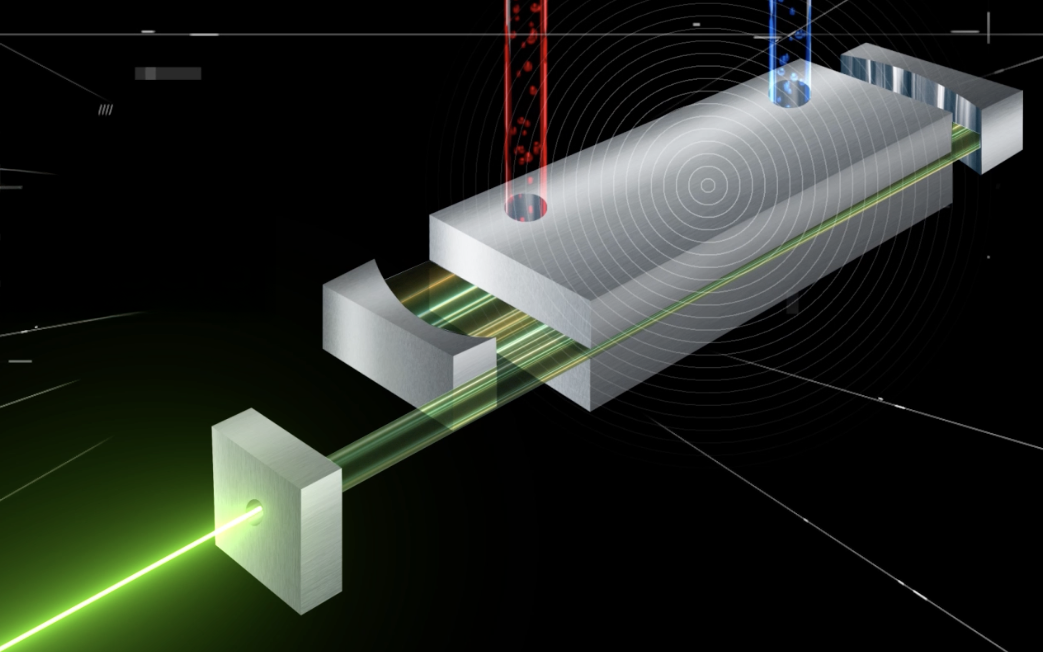

Luxinar, the UK-based laser technology company, has partnered with Austria-based Iradion Laser to offer carbon dioxide short pulse and ultrashort pulse lasers for lithium battery.

The companies claim lasers could improve lithium battery production, in terms of the laser notching and slitting of battery electrodes. The latter would be done using a 120W femtosecond laser.

The companies say that the laser technology reduces dust, chemicals and production delays caused by traditional tools. Laser cutting is a versatile machining process vital for two parts of the lithium battery manufacturing process.

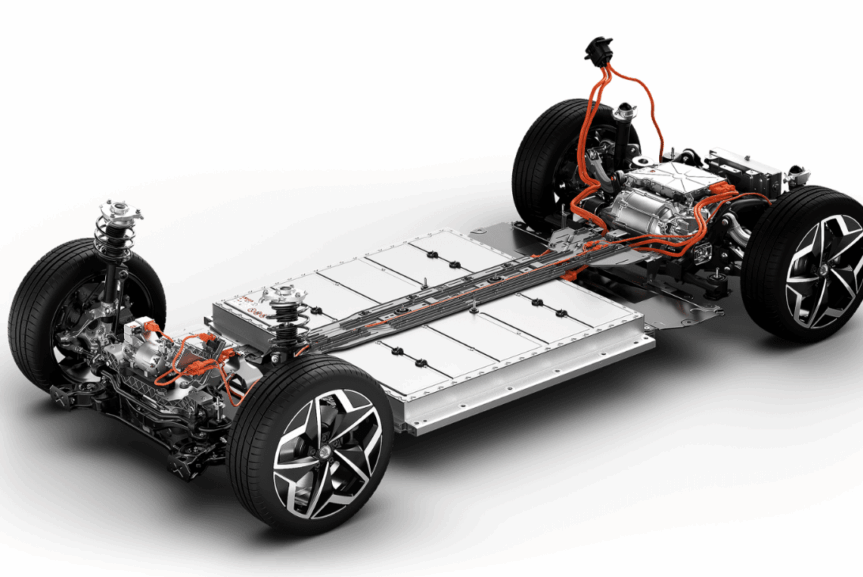

These are, according to both firms:

- At the slitting station to divide precisely the wide electrode coil into individual electrodes

- and at the separation phase to achieve the final electrode shape.

Femtosecond lasers offer an advantage by minimising the heat transfer during cutting. The burst of ultrashort pulses reduces the size of the heat-affected zone and improves the edge quality, reducing the risk of electrical shorts.

Conventional lasers, having a longer pulse duration, can affect battery performance through damage caused to the separator or electrode material.

The companies claim their femtosecond lasers will maintain a clear clearance width after cutting through multi-layered electrode material and optimise cutting speed.

Yannick Galais, sales director, Luxinar, said: “Our close cooperation with Iradion means we can offer our customers enhanced sales and service capabilities, with a wider choice of laser sources, applications and customer support.”

Pic: Luxinar