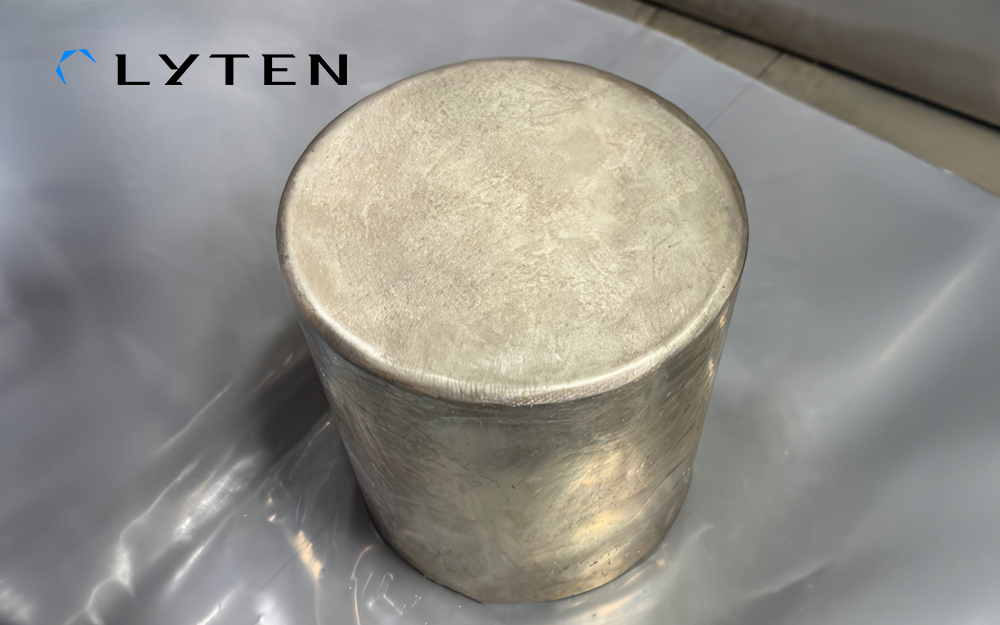

Pioneering lithium-sulphur battery maker Lyten has produced battery-grade lithium-metal foil using materials sourced only from the US.

Lyten used US-made lithium alloys and US-sourced lithium-metal to manufacture the material. Its lithium-metal feedstock is sourced from a facility in the Eastern region of the country.

The US company’s foils can be used on its lithium-sulphur battery manufacturing lines. It produces National Defense Appropriations Act (NDAA) compliant lithium-sulphur battery cells in San Jose, California.

The firm converts lithium alloys into proprietary lithium-metal foils in custom built extrusion and rolling equipment at its San Jose manufacturing facility.

The company began production of proprietary lithium alloys with the help of Creative Engineers in Pennsylvania, US. The companies collaborated to design and build lithium-metal alloy ingot manufacturing equipment.

The lithium-metal foil milestone comes as the country’s policymakers and defence agencies push to increase autonomy of its battery industry and its domestic critical materials supply chain.

Today, China dominates the battery materials supply chain, including processing and manufacturing a high percentage of the world’s battery-grade lithium. This creates a vulnerability for the US, especially amid the ongoing ‘trade war’ between the nations.

The company’s batteries use a sulphur cathode and a lithium-metal anode – rather than traditional lithium-ion materials such as nickel, manganese, cobalt, and graphite.

Dan Cook, Lyten co-founder and CEO, said by eliminating the use of these materials his company could focus on the ‘local supply and production of lithium’.

In February, Lyten signed agreements with California Sulphur Company, and a Port of Stockton company to secure US sourced, industrial-grade sulphur.

The material will be used at Lyten’s California manufacturing facilities in San Jose and San Leandro. It bought San Leandro in November 2024 from Cuberg, the advanced technology group of battery maker Northvolt, which filed for bankruptcy in Sweden in March this year.

The company will also use the sulphur at its planned 10GWh manufacturing plant in Reno, Nevada, which it announced last October.

Applications for Lyten’s ultra-lightweight batteries include energy storage, EVs, drones, satellites, micromobility, and defense.

In December 2024, Lyten and the Export Import Bank of the US announced a $650million LOI to fund the scale-up and delivery of the former’s lithium-sulphur technology for energy storage system applications.

Last year, Lyten announced:

- its integration into Chrysler’s Halcyon Concept electric vehicle

- plans to integrate lithium-sulphur into AEVEX Aerospace’s unmanned aerial vehicles

- the selection of its technology for demonstration on-orbit aboard the International Space Station (ISS).