A probe developed by engineers at the University of Washington (UW) to investigate how batteries work at the nanoscale level could lead to increased energy density.

Similar to atomic force microscopy, the new tool allows scientists to study how chemical reactions progress at atom and molecular level.

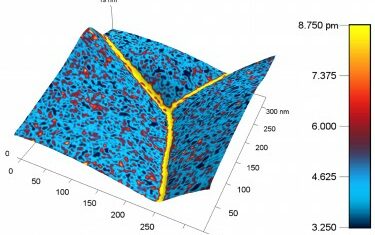

The team tested the probe by measuring the concentration of charged species in samarium-doped cerium and LiFePO4, materials used in lithium batteries.

“The concentration of ionic and electronic species are often tied to important rate properties of electrochemical materials — such as surface reactions, interfacial charge transfer, and bulk and surface diffusion — that govern the device performance,” said Jiangyu Li, UW professor of mechanical engineering.

“By measuring these properties locally on the nanoscale, we can build a much better understanding of how electrochemical systems really work, and thus how to develop new materials with much higher performance.”

The device identifies the battery’s Vegard strain-induced vibrations to show the concentration of ions and electronic defects near the probe tip.

An electrical current heats the probe’s cantilever to cause localised stress in the material to make the atoms and ions within the material move around, causing it to expand and contract (like wood soaked in water).

This movement causes the cantilever to vibrate, which is then measured using a laser beam focused on the cantilever.

However, the new system can only probe rates slower than the heat transfer processes in the vicinity of the tip.

The findings were published in the Journal of Applied Physics.