Two battery materials spearhead companies have joined forces to accelerate the development of future battery materials. NEO Battery Materials Ltd, the Canadian silicon anode developer, and Elementium Materials Inc, a Massachusetts-based battery materials company developing and scaling novel electrolyte formulations for advanced lithium-ion chemistries, have signed a collaboration agreement.

NEO will apply Elementium’s advanced electrolytes to its silicon battery platform for use in specialty commercial applications. The primary goal for the collaboration is to improve electrochemical performance metrics, especially ultra-fast charging and discharging capabilities.

Mr. Spencer Huh, CEO & President of NEO, expressed, “High-demanding, emerging downstream markets – such as power tools, humanoid robots, drone/UAV, and aerospace systems – require high-specification batteries in which silicon anodes and advanced electrolytes are indispensable components. Through this collaboration, NEO and Elementium are confident to deliver solutions that address these performance needs.”

Dr. Matthew Dawson, CEO of Elementium, commented, “We’re seeing strong market demand for high-performance silicon anode batteries. Elementium’s next-generation electrolyte unlocks the incredible potential of silicon batteries, and we are pleased to partner with NEO, one of the world’s leading silicon anode suppliers.”

Elementium’s electrolyte is based on a cutting-edge technology licensed from MIT. The advantages are high cell stability and long-time performance thanks to reduced degradation of the non-carbonate electrolytes. Elementium claims to offer compatibility with emerging anode and cathode materials, including silicon, manganese-rich, and high-nickel electrodes. While traditional electrolytes face corrosion, oxidation, and toxic gas formation issues, Elementium has engineered advanced electrolyte formulations to enhance battery stability, material robustness, and safety.

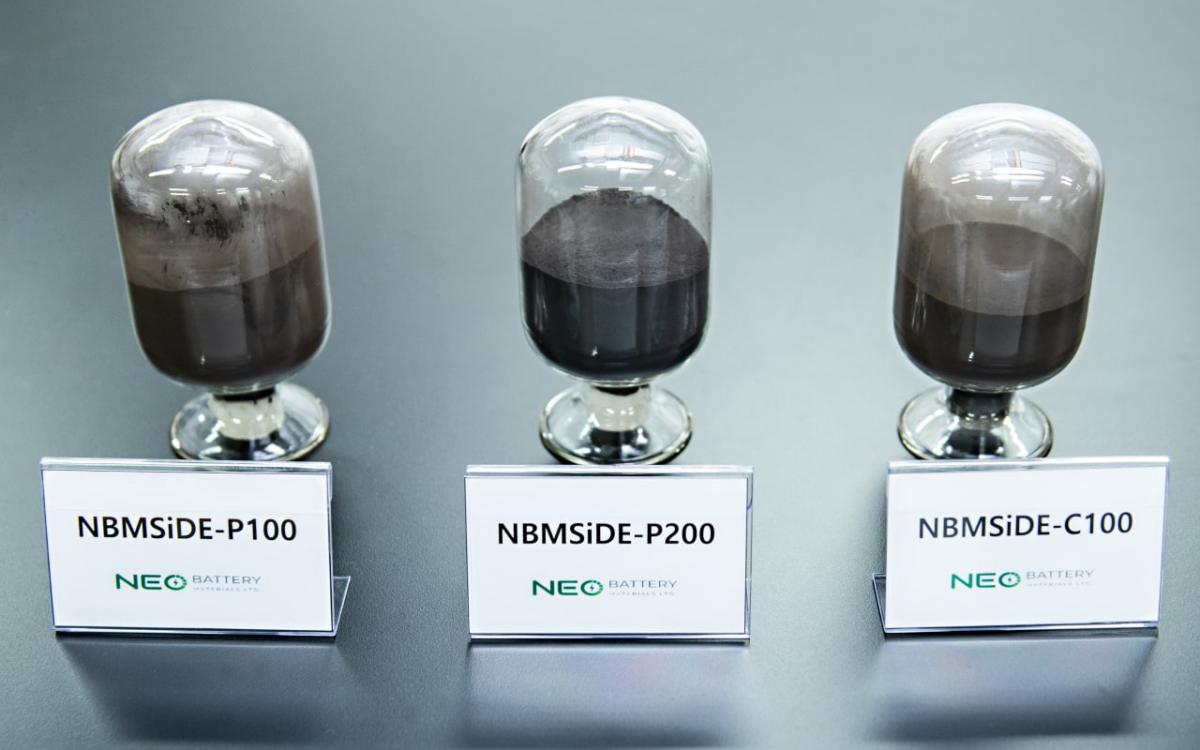

NEO Battery Materials’ patented technology employs elastic and carbonaceous nanocoating materials to encapsulate the entire surface area of silicon particles, to reduce mechanical stress from silicon’s volume expansion problem. The goal is to enable durability and stability in long-term cycling tests, high energy density, and ultra-fast charging capabilities.

New materials for anodes. Photo credit: Neo