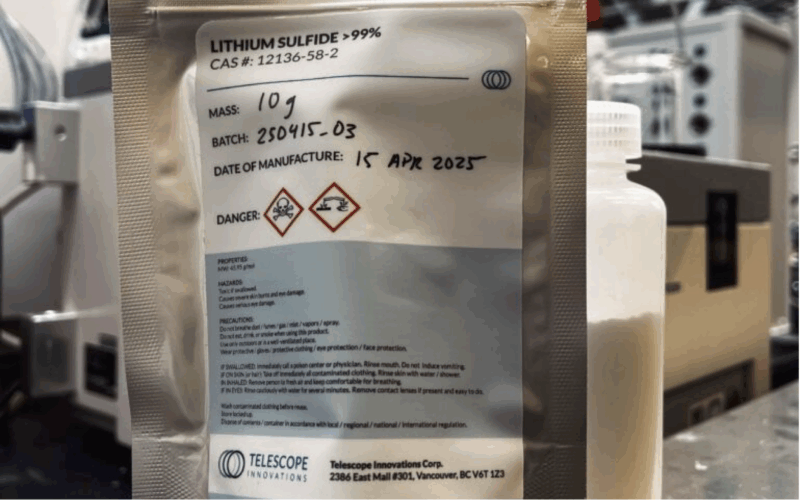

Standard Lithium, the Canada-based lithium development firm, has produced lithium sulphide for use in solid-state batteries (SSB) in collaboration with the chemical technology company Telescope Innovations, using a low temperature IP-protected method.

The new process involves the conversion of lithium hydroxide produced at Standard Lithium’s US-based demonstration plant in Arkansas into battery-grade lithium sulphide.

Samples of the sulphide have been sent to SSB companies in Asia and North America for on-going testing.

The firm claims that lithium sulphide is a key material for SSB chemistries yet is currently produced commercially only in small quantities at high cost.

Both firms said the new process comes with advantages such as feedstock flexibility with both lithium hydroxide and lithium carbonate being viable inputs, impurity tolerance, and lower processing temperatures said to reduce operating costs and bring safety benefits from avoiding high temperature conditions.

Dr. Andy Robinson, president and COO, Standard Lithium, said: “Whilst our principal area of focus, and capital allocation, is building the first DLE project in North America at our South West Arkansas Project Phase 1 with our joint venture partner Equinor, we understand that constant technological evolution is integral to staying at the forefront of this rapidly evolving industry. This recent work led by Telescope demonstrates that we are able to take lithium chemicals produced from the Smackover Formation in southern Arkansas and then transform them into the feedstocks required by the next generation of batteries. Our partnership with Telescope Innovations continues to be a “win-win” for our shareholders and their’s.”

Image: A sample of the lithium sulphide made via Telescope’s proprietary process. Credit: Telescope Innovations.