Researchers at Shanghai university have proposed a lithium plating detection system for batteries and an early warning algorithm for lithium-ion batteries.

The lithium plating model, which is claimed to have been validated via in situ characterisation methods, shows the detection accuracy as greater than 97.2%.

One of the greatest causes of safety accidents in electric vehicles (EVs) is when lithium batteries are negative plated, according to the researchers.

Lithium plating is when lithium builds up on the surface of the battery’s anode.

The electrode becomes polarised, and the lithium evolution rate goes past the insertion rate. It occurs when the local potential at the negative electrode is less than 0V, they said.

This can happen during fast charging, low temperatures or at high states of charge.

It includes the charging combustion accidents which have come all too common with lithium-ion EVs, they said.

Thus, they believe plating detection to be critical to guarantee the safe operation of lithium-ion batteries throughout the whole lifecycle.

They believe online lithium plating detection methods, while not requiring extra equipment, are inaccurate.

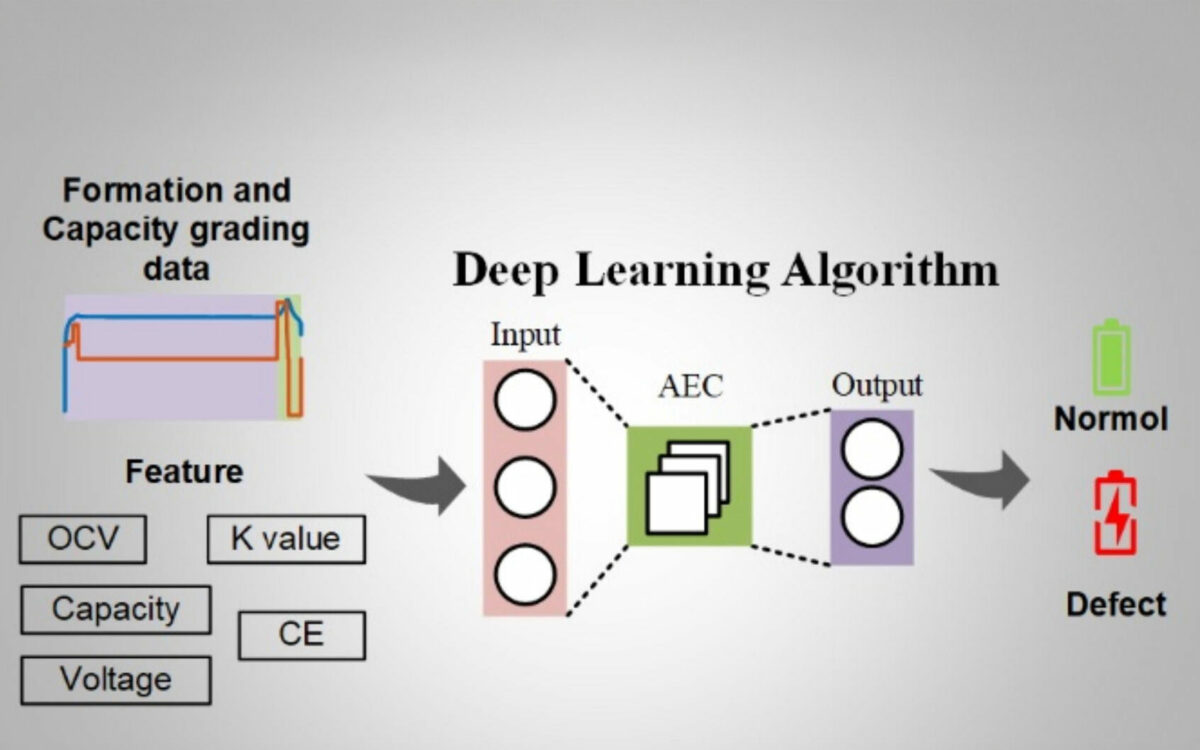

The system the researchers made collects and then conducts analysis on data collected during pulse charging to determine whether plating is happening based on the random forest machine learning model.

The researchers said they first conducted pulse charging experiments, so that they could get the basic electrical signals data.

After this, they looked at the normalised internal resistance from the pulse charging data to determine whether plating is happening.

The data must then be extracted, for which the researchers propose a method that involves a multi-feature dataset and machine learning. This is because there is a large volume of data poor feature information dimensions, they said.