Material Scientists at Penn State University have developed a three-dimensional polymer nanocomposite that could oust biaxially oriented polypropylene (BOPP) as a battery’s dielectric.

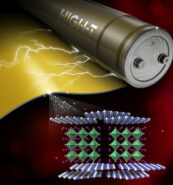

The ‘sandwich’ technology increases a battery’s energy density using boron nitride nanosheets in a polymer matrix for the outer layers, and barium titanate as the central layer.

The sandwich structure nanocomposite is called SSN-x, in which the x refers to the percentage of barium titanate nanocomposites in the central layer.

At 150ºc SSN-x and BOPP have similar charge-discharge energy, but SSN-x has several times the energy density of BOPP.

The new technology would allow battery makers to reduce the size and weight of the electronics and eliminate bulky and expensive cooling equipment required for existing BOPP technology.

Current BOPP technology used in hybrid and electric vehicles needs additional cooling equipment to prevent failure at high operating temperatures.

Qing Wang, professor of materials science and engineering and the team leader, said: “We have the top and bottom layers that block charge injection from the electrodes.

“Then in the central layer we can put all of the high dielectric constant ceramic/polymer filler material that improves the energy and power density.

“We show that we can operate this material at high temperature for 24 hours straight over more than 30,000 cycles and it shows no degradation.”

The results were published in the Proceedings of the National Academy of Sciences (PNAS).

The paper is titled ‘Sandwich-Structured Polymer Nanocomposites with High Energy Density and Great Charge-Discharge Efficiency at Elevated Temperatures’.