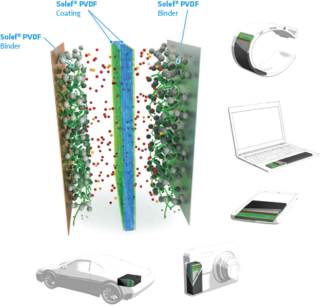

Belgian-based Solvay speciality chemicals showed its range of Solef® polyvinylidene fluoride (PVDF) materials for the battery market including its new PVDF technology for solvent and water based separator coatings for high-energy, high-safety and high-sustainability Li-ion batteries at Interbattery in Seoul Korea last month.

With Korean makers at the heart of battery development for the EV market, Solvay is the only PVDF supplier that uses both emulsion and suspension polymerization technology, thereby offering the industry the broadest range of high-performance binders and separator coating materials.

Solvay’s new Solef® 75130 PVDF offer for use with today’s most common ceramic coatings exhibits excellent cohesion within the ceramic coating particles as well as safe adhesion between the ceramic particles and the separator substrate, which is key in obtaining a more effective and long-term high-energy battery performance. In addition, it provides good lamination performance with electrodes, helps to minimize the internal resistance of the separator, and shows outstanding pore forming capabilities for separators with high ionic conductivity in Li-ion batteries. Depending on the design of the separator, it can be used as its main component or just as a thin coating layer.

Moreover, Solef® PVDF aqueous dispersions can eliminate the need for organic solvents, thus reducing the carbon footprint of battery manufacturers as well as their solvent recycling costs. In addition, due to its good wettability in electrolytes and its ease of processing at lower temperatures, it also results in a more sustainable process further characterized by lower energy consumption.