A US start up company has pioneered the use of ultra-thin Kevlar fibers to create a barrier between the electrodes in a lithium-ion battery.

The breakthrough by researchers at the University of Michigan should prevent the kind of short circuits in Li-ion batteries which caused the electrical fire in Boeing’s 787 Dreamliner aircraft in early 2013.

The barrier, made with the nanofibers extracted from Kevlar, works by stifling the growth of dendrites that can become unwanted pathways for electrical current.

Dendrite growth threatens the safety of batteries by piercing the ion-transporting separators between the cathode and anode.

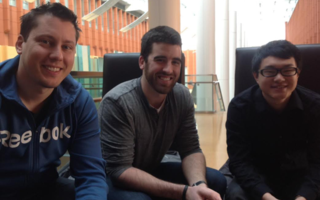

The researchers – John Hennessy (CEO), Dan VanderLey (CIO, CMO) and Long Qian (CFO) – have co-founded Elegus Technologies to market the discovery.

The team believe they have found the dendrite-suppressing material in a composite made from the aramid nanofibres assembled in a layer-by-layer manner with poly(ethylene oxide).

The patent-pending process is based on transformation of para-aramid threads into membranes with pores in the 15-20 nm range. Lithium dendrites are generally 20 to 50 nms across at the tip.

It means the porosity of the membranes is smaller than the growth area of the dendrites so the aramid nanofibres eliminate ‘weak links’ where the dendrites pierce the membranes.

Li-ion batteries can experience problems when the barrier separating the electrodes allows lithium atoms to build up in a fernlike structure that eventually breaks through the membrane to provide a new pathway for electrons and cause a battery to short-circuit.

Elegus is now in talks with four potential manufacturing partners, and expects to make a selection by June, VanderLey told Cio-today.com.

The breakthrough should increase Li-ion battery safety, longevity, and performance.

The researcher’s hope to begin mass production of the safer, rechargeable batteries in late 2016, and will market the development through their start up company Elegus Technologies.