Australian resource and mineral processing technology company TNG has hired an engineering group to undertake a technology and process design study for the development of its vanadium electrolyte production facility.

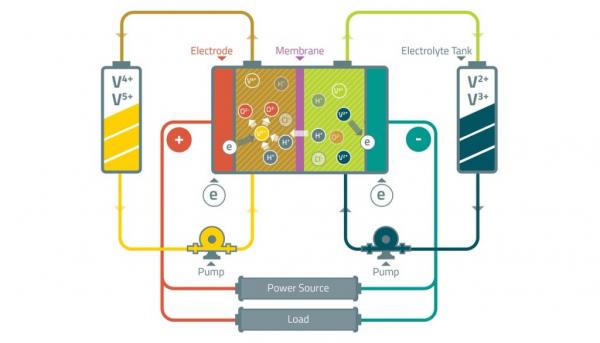

Perth-based METS Engineering (METS) is due to begin the study on behalf of TNG’s vanadium redox flow battery (VRFB) business, which will be owned by TNG’s 100%-owned subsidiary TNG Energy.

The study will deliver Australian preliminary process design documentation for the vanadium electrolyte facility, which will include all aspects of building the plant.

The process design will be driven by a comprehensive technology study that will evaluate available technologies, optimisation opportunities and previous work completed by TNG, to determine the most appropriate processing route.

The study is expected to take up to three months to complete and will support a decision to move into the design and planning phase.

A metallurgical test-work program will also be developed and implemented to help validate the process design and VE production specifications.

The VRFB business was established as a result of TNG producing high specification, commercial-grade vanadium electrolyte in 2016.

TNG plans to produce its own vanadium product from the 100%-owned Mount Peake Vanadium-Titanium-Iron Project in the Northern Territory.

The company aims to produce 6,000 tonnes per annum of high-purity vanadium pentoxide from the Mount Peake Project, in addition to titanium dioxide pigment and iron ore fines products.