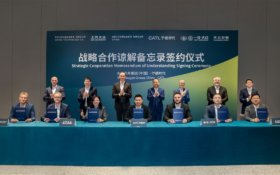

UK’s independent battery start-up Volklec has announced plans to make EV batteries with technology licensed from Chinese designer and manufacturer Far East Battery (FEB).

In a unique technology and knowledge transfer agreement Volklec will manufacture advanced lithium-ion batteries, starting this year. Production will be launched from the UK Battery Industrialisation Center (UKBIC) in Coventry, a partly government-funded factory.

The company will be supported by a partnership team of engineers and other specialists from FEB in China to ensure high yield and quality.

The company will manufacture two specifications of advanced lithium 21700 cylindrical battery cells starting with a proven cell using NMC chemistry, aimed at e-mobility and energy storage. This will be followed by an innovatory ‘power cell’ aimed at the specialist high-value manufacturing sector, including aerospace, marine, automotive and off-highway. The cells are already available to order.

The company will use the current 100MWh production line at UKBIC to manufacture the energy cell. A subsequent 1GWh production line is due to be installed by the end of 2026 to produce the ‘power cell’.

The management team is formed of highly experienced executives from commercial, technical and EV businesses with a wealth of experience in the battery manufacturing and electrification sectors. They lead a group of technical specialists. Executive Director Phil Popham had this to say:

“There is an urgent need for new independent manufacturers to secure the battery supply chain in the uk. There is no greater transformation today than the electric revolution in transport and mobility as the British start-up scene is thriving from motor sport to heavy-duty off-highway and most things in between. But there is a substantial gap in the supply chain. The UK is particularly strong in the specialist and hyperform sectors which need surety of supply with quality and reliability. Our mission is to help these innovators thrive.”

Volklec’s road map includes the development of a 10GWh giga factory at an investment cost of more than a UK£1bn (US$1.2bn). The company hopes this will create more than 1,000 new highly-skilled jobs by 2030. BEST previously reported on plans, that have yet to come to fruition, to build a gigafactory next to Coventry Airport.

FEB will help with engineering expertise and also allow access to its raw material supply chain to reduce costs.