The Swedish Västerås-based company Quintus Technologies, specialising in high pressure solutions, and the Laboratory for Energy Storage and Conversion (LESC) at the University of Chicago Pritzker School of Molecular Engineering, and the University of California, San Diego, have entered a research partnership with the goal to improve the performance of solid-state batteries.

One problem with solid-state batteries is that the use of solid ceramics instead of liquid electrolytes in batteries (that is expected to increase safety thanks to reduced risk of fire, as well as improved energy density and charging capabilities) meets technical problems with the manufacturing of electrodes.

Prof. Y. Shirley Meng from the University of Chicago explains: “Work with new layers of electrolyte materials indicates that the common uniaxial methods such as calendaring, or hot pressing, lead to insufficient electrode density and lower electrochemical performance. Therefore, warm isostatic pressing is labelled a key technology in creating sufficient particle-to-particle contact.”

Studies have shown that isostatic pressure is the only way to close the porosity in coated composite layers inside solid-state batteries effectively to a degree that creates peak electrochemical performance. This allows for uniform compression of small and large multilayer cells, preserving the internal layered structure of components, without creating local defects or inhomogeneities.

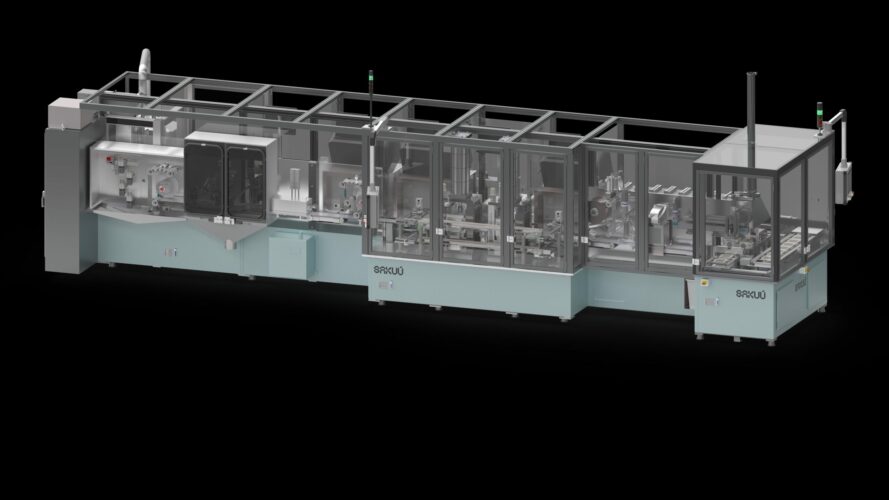

The MIB 120 battery press from Quintus can reach pressures of 600 MPa (87,022 psi) and temperatures of 140° C (284° F). The press is designed to have a very high temperature uniformity, which guarantees a high reproducibility of cells for mass production.

“Prof. Meng is one of the leading scientists in ASSB worldwide, and we are very happy to enter this collaborative partnership,” states Johan Hjärne, CEO of Quintus Technologies. The press is scheduled to be installed at the LESC facility in Chicago in July 2025.

Image: Isostatic press. Credit: Quintus Technologies