BMW, the German automaker, will start production of battery EVs at its Rayong factory in Thailand in the second half of 2025. It currently manufactures plug-in hybrids and ICE vehicles at the plant. The first step of the new venture will be to set up a local production plant for fifth-generation high voltage batteries. The battery systems for the hybrids are produced in Thailand.

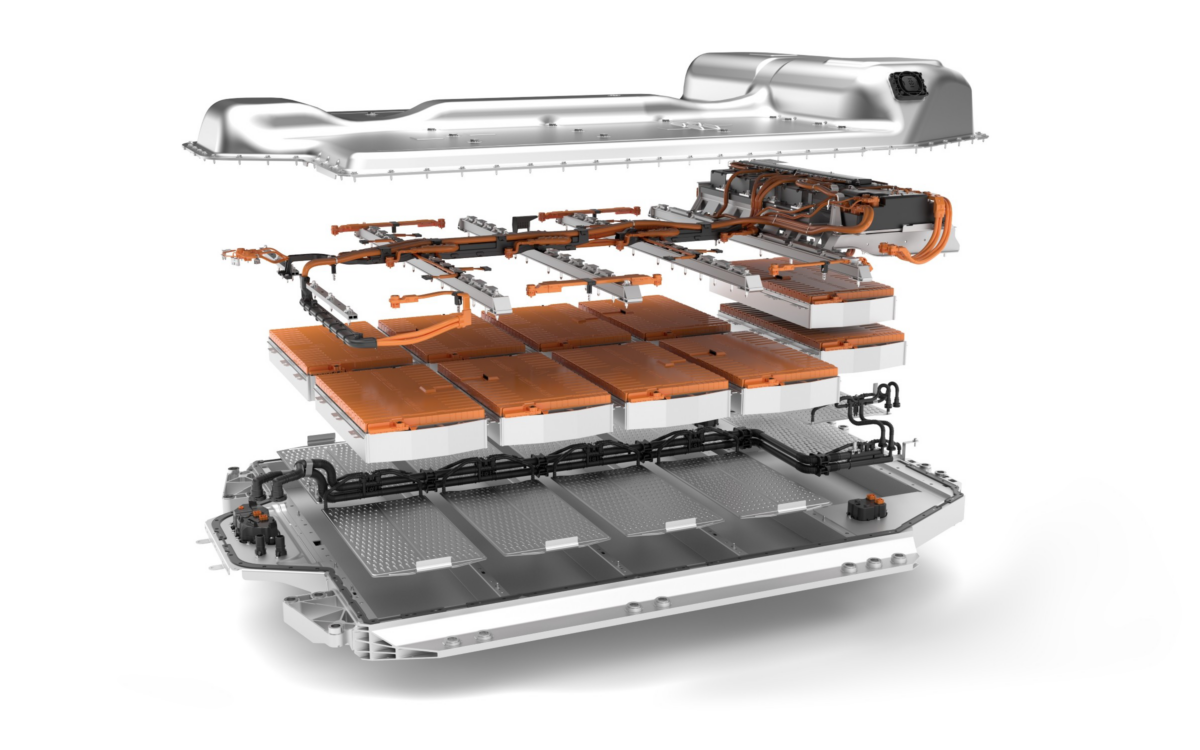

Generation five batteries involve prismatic cells, which are assembled into ready-to-install battery pack modules. The sixth generation of batteries to be introduced in 2025 is based on cylindrical cells, but also on a cell-to-pack concept without modules.

The fifth-generation battery packs in the BEV and PHEV applications across SUV and Sedan platforms use prismatic cells from Samsung SDI and CATL in a number of sizes. The modular approach is designed for repair and second life, the company said.

The future high-voltage battery assembly plant covers 4,000 square meters and represents “an important expansion” BMW’s manufacturing in Thailand. According to BMW, imported battery cells will be assembled into modules in the new production facility and then integrated into the high-voltage battery.

BMW said it has invested more than ฿1.6 billion ($44 million) in the project, a significant share of which – almost ฿1.4 billion ($39 million) – will be used to buy state-of-the-art equipment and systems.

“Local production of high-voltage batteries in Rayong is the next logical step in the continued electrification of our production network,” said Milan Nedeljković, board member for production at BMW.

BMW has been producing high-voltage batteries in Thailand for locally made plug-in hybrids since 2019. The Rayong plant manufactures around two dozen BMW, MINI and BMW Motorrad models for the Thai and ASEAN markets. In 2023 output totalled more than 12,000 cars and almost 11,000 motorcycles.

Photo: 5th generation battery pack for the ix3. BMW