UK-based Altilium, a clean tech group, signed a memorandum of understanding with German tech chemical company Helm to develop a sustainable domestic supply of lithium in the UK.

The idea is to reduce UK reliance on imported raw materials. They will also research the development of alternative lithium processing techniques.

The subsidiary LevertonHELM will initially qualify technical-grade lithium carbonate from end-of-life EVs and production scrap at Altilium’s Devon ACT1 recycling facility. It is expected that this will lead to off-take and tolling agreements for supply of recycled lithium in the UK.

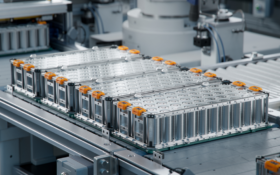

Altilium’s ACT2 facility in Plymouth can recover lithium and other battery metals from 300kg of black mass per day using its propriety Eco Cathode process. The plant will produce cathode active materials (CAM) for the motor industry as well as high levels of lithium for the British supply chain.

A planned north-east England facility in Teesside will be one of the largest EV battery recycling plants in Europe, having the capacity to process scrap from over a 150,000 EVs per annum, producing 30,000 tonnes of CAM. This is expected to meet 20% of the UK’s 2030 needs.

Stefan Berner Beltran, principal engineer and lithium raw materials lead at Altilium said: “This is a great opportunity to support the UK’s efforts to secure such an important mineral for the energy transition. By working together on alternative technologies we can unlock the most value from domestic urban mining aiming for greener and more efficient refining processes.”

Altilium has been supported by the UK government.