Battery maker APB Corporation is preparing to mass-produce lithium-ion batteries in Japan after licensing technology know-how from vehicle OEM Nissan.

Backed by investment from major companies, Tokyo-based APB plans to build a factory manufacturing batteries using Nissan’s bipolar structure all-polymer technology.

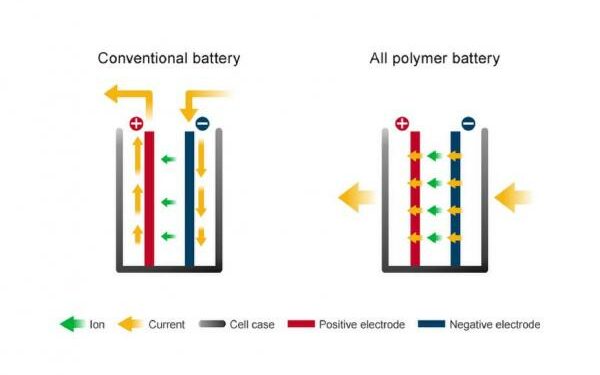

The technology replaces the liquid electrolyte and metal electrodes used in conventional batteries with polymers.

The front and back of the battery cell forms part of the battery case and are made of a either a negative or positive polarity polymer current collector. A bipolar structure is created by stacking these cells together.

Nissan says the technology increases charging capacity relative to battery volume, enhances safety by replacing liquid electrolytes with polymers and lowers cost.

“We believe the widespread adoption of this technology will contribute to fulfilling the U.N’s sustainable development goals and help realise a sustainable, low-carbon society,” said Hideki Kimata, vice president of the corporate strategy and business development division at Nissan.

Nissan began researching and developing lithium-ion batteries in the early 1990s.