Empa, the Swiss federal laboratories for materials science and technology, are using new funding to develop the Aurora battery robot to speed up automated cell component selection and processing.

Corsin Battaglia, head of Empa’s Materials for Energy Conversion laboratory in Dübendorf and professor at research institute ETH Zurich, said future plans include autonomous material selection, assembly and analysis of battery cells in the laboratory.

The aim is to achieve a roughly 10-fold acceleration of current development processes, he added. Empa is working together with the company Chemspeed Technologies.

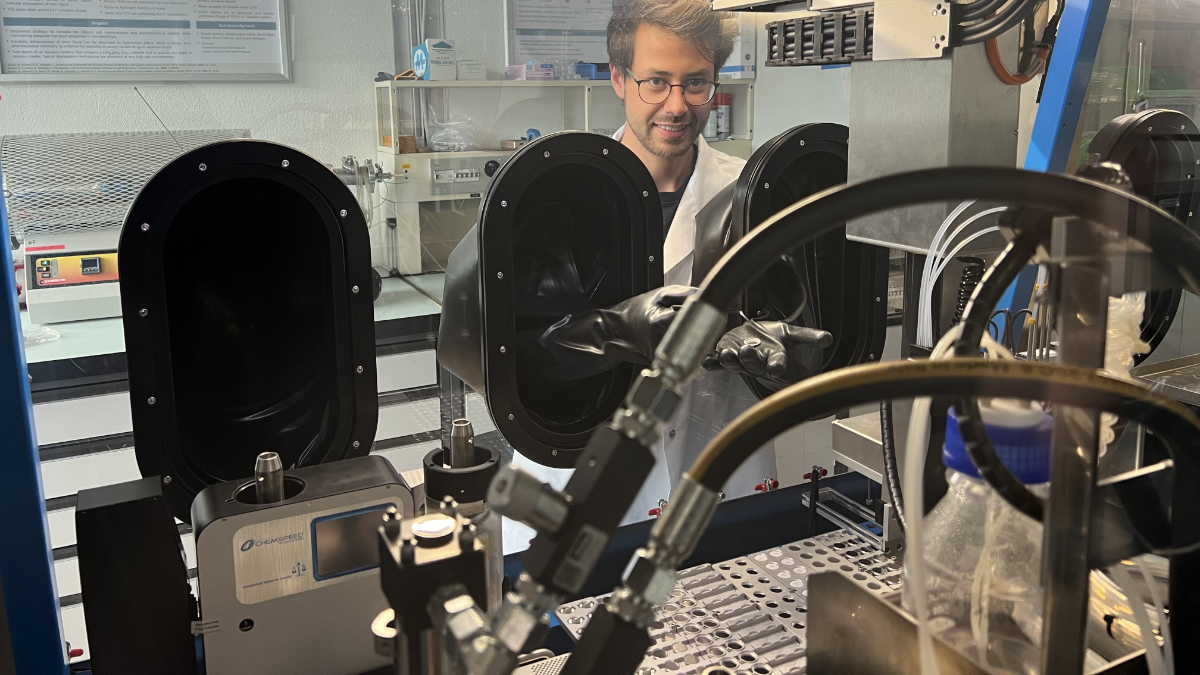

Empa researcher Enea Svaluto-Ferro said the robot weighs, doses and assembles the individual cell components with constant precision. It also carries out charging cycles and other repetitive steps. That allows researchers to use the generated data to drive the innovation process forward.

The lab will train Aurora to work autonomously. It said: “Using machine learning, the Aurora AI could thus create mathematical models and decide which experiments should be carried out in the next step and which materials and components are particularly promising candidates for the desired battery application.” The platform works independent of materials and chemistry.

The Aurora project is part of the European research initiative Battery2030+. It was recently awarded over €150 million ($160 million) in funding by the EU.

The robotic platform is embedded in the ETH Board’s Open Research Data initiative, which aims to promote digitisation in research and make data freely available to the scientific community.

Photo: Empa researcher Enea Svaluto-Ferro works with the battery robot Aurora. Credit: Empa