Swiss battery metals firm Blackstone Resources announced on 16 September it had achieved a series of milestones for 3D-printing lithium-ion solid-state batteries.

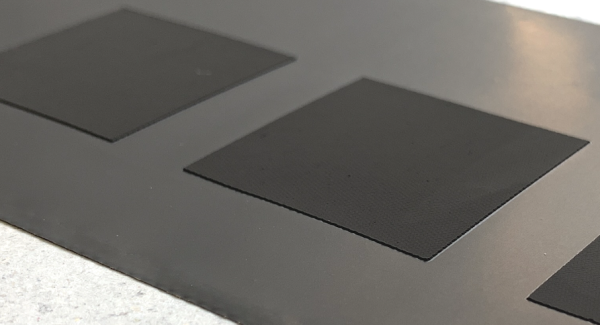

Through its German subsidiary Blackstone Technology, the company has tested solid-state battery prototypes, and is now developing the 3D-printing technology required to print them for mass production, including the battery composites, casings and electrolytes.

An automated 3D-printing production process could save up to 70% of the traditional Capex used to produce solid-state batteries, say the firm.

The Blackstone Technology process could offer advantages over conventional battery cell design that use liquid electrolytes, including: lower costs; higher level of production flexibility of the cell format; and 20% increase in energy density.

The company claims that by using the technology the amount of materials that do not store energy in a battery, such as copper and aluminium, could be reduced by up to 10% independently of the electrode chemistry.

Holger Gritzka, CEO of Blackstone Technology, said: “Together with the developments we have made in 3D-printing battery technology to date, this development paves the way for the mass production of solid-state battery cells. In addition to major markets such as the automotive industry, marine applications and new 5G wireless networks would benefit from the advantages that 3D-printed solid-state cells can offer.”