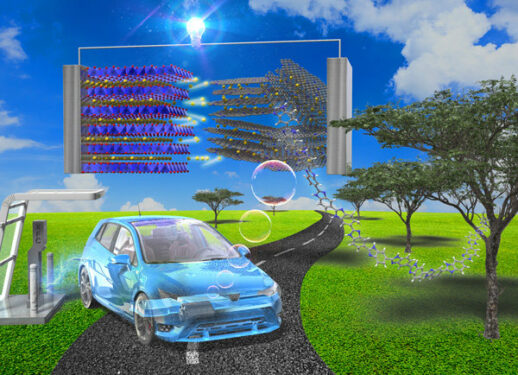

Scientists from Japan Advanced Institute of Science and Technology (JAIST) have developed a new anode material that could overcome the slow charging times of conventional lithium-ion batteries.

The technology uses a carbon-based anode with ∼17 wt% of nitrogen doping (introduction of nitrogen impurities) with charging capability at 18.6 A g−1.

The findings could pave the way to fast-charging and durable batteries for electric vehicles as the industry looks to cut the charge time of EVs from around 40-minutes to be below 15 minutes.

The team of scientists from JAIST was led by professor Noriyoshi Matsumi, and included: professor Tatsuo Kaneko; senior lecturer Rajashekar Badam,; JAIST technical specialist Koichi Higashimine; JAIST research fellow Yueying Peng, and JAIST student Kottisa Sumala Patnaik.

The team’s findings were published online in the journal Chemical Communications.

Professor Matsumi said: “The extremely fast charging rate with the anode material we prepared could make it suitable for use in EVs. Much shorter charging times will hopefully attract consumers to choose EVs rather than gasoline-based vehicles, ultimately leading to cleaner environments in every major city across the world.”

New battery material

The precursor material for the anode is poly (benzimidazole), a bio-based polymer that can be synthesized from raw materials of biological origin was calcinated at 800°C.

Durability tests using half-and full-cells showed the proposed anode material retained around 90% of its initial capacity after 3,000 charge-discharge cycles at high rates.

The researchers verified the successful synthesis of the material and studied its composition and structural properties using a variety of techniques, including: scanning electron tunneling microscopy, Raman spectroscopy, and X-ray photoelectron spectroscopy.

A method being investigated to cut charge times is increasing the diffusion rate of lithium ions, which in turn can be done by increasing the interlayer distance in the carbon-based materials used in the battery’s anode.

While this has been achieved with some success by nitrogen doping there is no method easily available to control interlayer distance or to concentrate the doping element.

Modifications to the structure of the polymer precursor could lead to even better performance, which might be relevant for the batteries not only of EVs, but also of portable electronics.