The new Chinese owner of Nissan’s former international lithium-ion business has pledged to slash the cost of manufacturing electric vehicle battery cells to around US$50 per kWh by 2025.

Envision Group CEO Zhang Lei, whose Shanghai-based group recently finalised its acquisition of the Automotive Energy Supply Corporation (AESC), said: “The EV sector is facing three major challenges: safety, cost and grid integration. Digitalisation is the key to all of these.”

Envision will step up R&D to improve battery safety, performance and integration with intelligent energy systems including its own lithium-based AIoT (artificial Intelligence of Things) battery tech.

Shoichi Matsumoto, CEO of Envision AESC, said: “We have all the data on the battery life cycle through years of cooperation with Nissan, and fully tested the performance, safety, durability and reliability of products.”

“To date, our lithium-ion batteries manufactured in Japan, the US, and Europe have been installed in over 430,000 electric vehicles with a zero critical malfunction such as catching fire.”

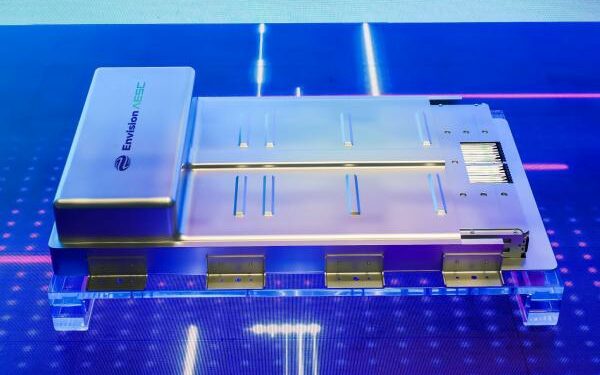

Envision formally unveiled its ‘Gen5-811 AIoT battery’, targeting the EV market, at the 18th Shanghai International Automobile Industry Exhibition on 17 April. The battery will have a high energy density of about 300 Wh/kg, the company said. The product will be mass-produced at the Envision AESC Wuxi plant in China in 2020, with a total annual production capacity of 20GWh.

Last month, Bloomberg New Energy Finance’s head of energy storage, Logan Goldie-Scot, forecast the price of an average battery pack to be around $94/kWh by 2024 and $62/kWh by 2030. However, Goldie-Scot said some companies were likely to “undershoot and go to the market with lower prices sooner”.