The trend for electric mobility and the demand for lithium-ion batteries has surged beyond expectations and is set to continue. This has led to a boom in lithium-ion cell production. Cheryl Thibault, global product manager battery segment at Munters, explains the importance of dry room climate control and how her firm is optimising their design.

As countries look to reduce or ban vehicle-related emissions, some as early as 2030, battery manufacturers need to increase capacity and capability when it comes to producing lithium-ion batteries.

Manufacturers want batteries that have higher storage capacities, last longer, and charge faster. Through research and development this is all realistic, but one of the most important factors will continue to be the production environment.

Lithium and other materials are highly reactive to moisture, so when using them as the basis for battery production, it is essential to operate in humidity controlled dry rooms. There are a number of reasons for this, from ensuring the highest possible quality and production yield to providing a safe working space for employees. Issues with moisture can reduce production uptime leading to lost product, significant costs and negative impacts on the environment and brand reputation. Typically, certain battery production and assembly process steps require a dry room such as mixing, coating, stacking, laminating, electrolyte filling, packaging and formation. Separate dry rooms may be used for different process steps, and each may have different climate requirements.

As these rooms are so essential to the process, and influential on the quality of the end product, manufacturers need to know what to look for in a dry room, and how to ensure they have the best humidity control solution to fit requirements. So, what is a dry room?

Dry room importance

A properly designed dry room will include a wall and roof panel system with vapour-tight construction, with all-welded ducting to minimise moisture infiltration; air locks for personnel entry/exit and material air locks for raw material and equipment movement. Air locks should be kept at positive pressure to prevent infiltration. Floors should provide a conductive vapour barrier to eliminate static electricity.

Dry rooms, like clean rooms, will require some level of particulate filtration and this will depend on customer specifications for ISO class and acceptable particle count. Typically, ISO 6, 7 or 8 is specified.

Airflow design is also important; careful consideration of air motion and airflow patterns is important in the design of the dry room.

More important than anything else, a dry room’s integrated dehumidification system must be able to meet the right dew point— the temperature at which water vapour in ambient air starts to condense. The lower the dew point, the lower the water vapour content in the air.

Even small amounts of moisture in the air can ruin the integrity and compromise the quality of the finished battery. This can impact anything from the cell performance to the lifetime of the battery.

The generally accepted dew point for lithium battery production is -40°C (< 1% relative humidity), although there are signs this will drop further due to new battery chemistries that are more moisture sensitive. Glove boxes can be used for small-scale R&D laboratories, but for pilot production or high-volume production, more equipment and more space are needed.

The only alternative to reach the necessary dew point for high-volume production is by using efficient dehumidification technology designed specifically to create this environment for the dry room.

A typical specification for a dry room may call for the room dew point to be at -40°C. This equates to about 0.08g/kg (grams of moisture per kilogram of dry air), 0.55 gr/lb (grains per pound air) or 79 PPMw (parts per million by weight).

The control level and internal moisture load in the room are used to determine the size and airflow requirement of the dehumidification system. The internal moisture load comes mainly from people working in the dry room and infiltration from air lock openings. Extremely dry ‘supply air’ is provided into the dry room while ‘room air’ is exhausted back to the dehumidifier as ‘return air’. By providing ‘supply air’ at a lower dew point than the ‘room/return air’, you can create a differential that is equal to the moisture load in the room.

Typically, some air from certain battery production tools is exhausted to atmosphere. Therefore, some outside ‘makeup air’ is mixed with the ‘return air’ to balance the airflow. Since outside air has a high moisture load, especially in summer conditions, mechanical cooling should be used to pre-cool the mixed air and condense-out excess moisture before the dehumidifier. This improves conditions for creating the -40°C dew points required for the dry room.

How it works

The optimal way to achieve the best dry room is through desiccant dehumidification. The better the technology, the drier the air can be, and the less energy that needs to be expended to achieve it.

Silica gel is the industry standard desiccant for dehumidification applications. It works very well for room dew points above -30°C. However, Munters offers a mix of silica gel and molecular sieve desiccants to create a desiccant rotor that has higher performance and provides better efficiency for low dew point dry rooms at less than -40°C dew point (DP).

Desiccant choice is important, but equally important is the system design and energy-efficient purge technology used. Desiccant rotor dehumidifiers use heated ‘reactivation air’ to continuously regenerate the rotor after moisture is adsorbed from the ‘process air’. A typical dehumidifier uses about three-quarters of the rotor for the ‘process air’ and one-quarter of the rotor for the regeneration step. Once regenerated, the desiccant wheel rotates back to the process area for further moisture adsorption.

But, to achieve low dew points, the system should add a purge section to capture any residual moisture in the wheel and to recover heat to improve the systems’ energy efficiency.

Green PowerPurge™ technology

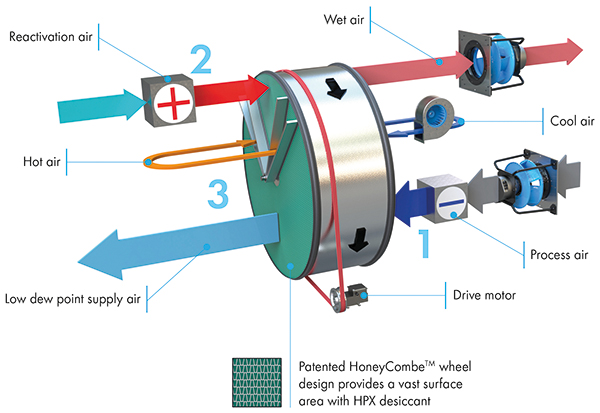

Munters’ patented Green PowerPurge™ technology (Fig 1) reduces the required reactivation energy by up to 45%. With Green PowerPurge™, a slip stream of air is recirculated with a small fan to cool and heat the rotor media, improving reactivation efficiency. The ‘purge air’ reduces energy needs and improves desiccant performance. Adsorption and desorption follow each other continuously.

1. Process air (return air from dry room plus fresh outside air) passes through the drying wheel and leaves as low dew point supply air

2. Heated reactivation air collects the moisture from the drying wheel and is exhausted as “wet” air

3. Green PowerPurge™ loop provides additional energy recovery by recovering the heat left over in the wheel after reactivation, which is then used to preheat the wheel media before reactivation

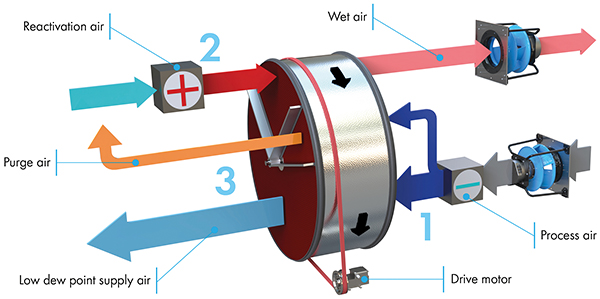

Industry standard energy purge

The industry standard energy purge (fig 2) incorporates some energy recovery but it is not as effective as Green PowerPurge™. Here we have three zones for process, regeneration and purge. Instead of a loop of recirculating air, a slipstream of air is stolen from the ‘process air’ and is sent through the purge section to recover heat from the wheel. The ‘purge air’ is then heated and used as ‘reactivation air’. The resulting low dew point ‘supply air’ volume will be less than the process inlet volume because this ‘purge air’ is diverted. For a given rotor size, the industry standard purge delivers less ‘supply air’ than the Green PowerPurge™ design. This needs to be taken into account when determining the dry room airflow requirement.

1. Process air (return air from dry room plus fresh outside air) passes through the drying wheel and leaves as low dew point supply air

2. Heated reactivation air collects the moisture from the drying wheel and is exhausted as “wet” air

3. Purge air provides nominal energy recovery by recovering heat from the wheel as it exits the reactivation section and supplements reactivation air

The dehumidification system will require energy for refrigeration/pre-cooling and for heat for reactivation of the desiccant rotor as mentioned above. The rotor is typically regenerated at 140-155°C (284-310°F). Munters Green PowerPurge™ technology recovers heat from the rotor and therefore reduces reactivation energy up to 45%. The source of reactivation energy can be natural gas burners, electrical heaters or steam.

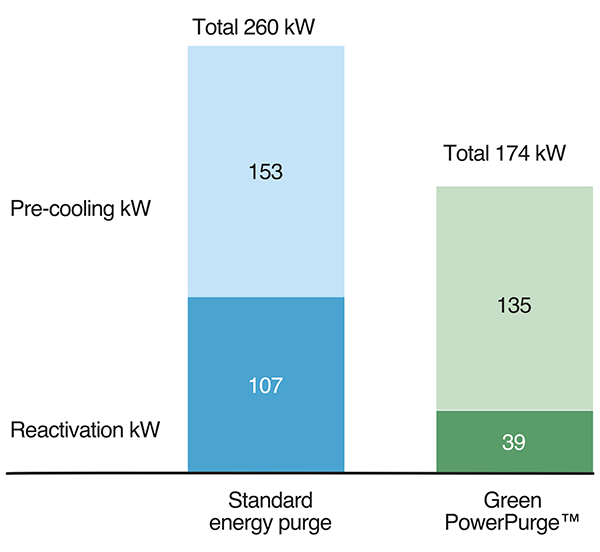

The case below compares energy usage for dehumidification systems using the Green PowerPurge™ and industry standard energy purge technologies. Reactivation gas consumption and refrigeration/cooling energy consumption is shown for an example dry room requiring 16,320 m3/h (9,600 cfm) of ‘supply air’. As you can see, reactivation energy is reduced considerably, and total energy consumption is reduced by more than 30% with our system.

Annual energy savings with Green PowerPurge™ is about €24,000 ($28,000) per year for this single unit. When we multiply that by 20 systems for a typical gigafactory, it amounts to annual savings of about €500,000 ($586,000).

Green PowerPurge™ also offers a higher volume of air through the rotor because there is no stolen ‘purge air’. This means higher airflow rates are delivered to the dry room. A higher supply airflow means smaller equipment can be used or fewer systems in total. The system also provides equipment designers with more tools to work with in order to optimise the best solution for each dry room project.

When it comes to preparing for the future, you will need the best in dehumidification performance, cost-effectiveness and energy efficiency. As scientists uncover more powerful chemistries and work to further develop nickel-based cathodes and solid-state batteries, dry room dew points are expected to drop even further, perhaps as low as -60°C DP. In order to keep costs down for humidity control, manufacturers will need optimised purge designs, including next generation ultra-low dew point solutions from Munters at lowest energy costs.

Optimising dry room

If you are designing a dry room, it is important to consider that over the life of the dry room the operation expenditure (OPEX) is likely to be many times that of the original capital expenditure (CAPEX).

|

Munters Green PowerPurge™ |

Standard energy purge |

|

|

Annual reactivation gas |

EUR 10,249 |

EUR 28,120 |

|

Annual refrigeration |

EUR 47,304 |

EUR 53,611 |

|

Annual total costs |

EUR 57,553 |

EUR 81,731 |

|

Annual savings with GPP |

EUR 24,178 (30%) |

|

Supply airflow rate |

16,320 m3/h |

|

Ambient air conditions |

32°C DB, 22 g/kg |

|

Room conditions |

20°C DB, 0.07 g/kg (-41°C DP) |

|

Operating hours per year |

8,760 |

|

Utility cost assumptions |

|

|

Refrigeration costs |

EUR 0.04 per kWh |

|

Natural gas costs |

EUR 0.03 per kWh |

As dry rooms are costly to run, total annual energy savings of 30% can make a real difference to your bottom line, offering a quick return on investment alongside a lower total cost of ownership (TCO).

With proper service, your equipment will receive the attention and maintenance needed to reach its maximum life expectancy. The knowledge and expertise of Munters’ global service network will ensure optimal operation, minimum energy consumption, and extension of the life of your investment. This means you can focus on providing the best and most efficient power of the future.

Finding the right solution requires the right expert partner with the best technology. Munters can offer the most advanced, efficient dry room dehumidification solutions. We know that the design process and partnership is important, and we are there to offer advice and answers at every step of the way.

The adoption of electric vehicles is accelerating since cost-effective high-volume battery manufacturing is now coming online. Factory energy costs significantly impacts the ultimate battery cost and thus the electric vehicle cost to the consumer.

Choosing the most energy-efficient dry room solution incorporating Munters’ Green PowerPurge™ dehumidification technology will reduce factory OPEX, allowing more competitive battery prices that fuel market growth. We invite you to the advent of a more sustainable energy future.