In Tesla’s bombastic modus operandi it was billed as Battery Day, and the company didn’t fail to raise eyebrows with a number of announcements aimed to revolutionise the battery industry.

Among the declarations made on 22 September were the plans to halve the cost per-kilowatt-hour of batteries, develop a dry electrode-coating manufacturing process and increase nickel content in its lithium-ion cells.

Tesla CEO Elon Musk said: “We’ve got to get the cost of batteries down and be better at manufacturing. The curve of cost-per-kilowatt of batteries is not improving fast enough.”

That said, maybe the biggest ‘game changer’ among the proposed developments to battery architecture is tab-less batteries, which Musk says will bring down $/kWh costs by 14%.

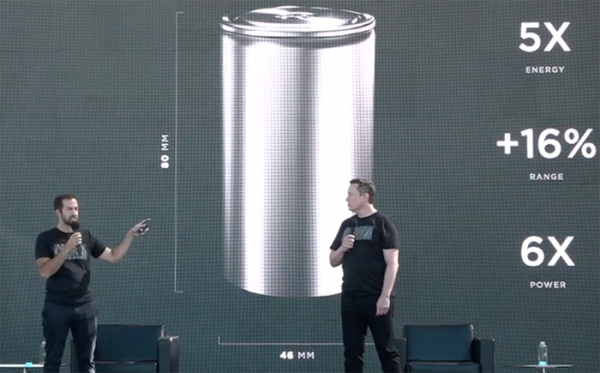

The new 4680 cylindrical cells promise five times the energy, increase EV range by 16% and deliver six times more power over its existing 2170 batteries, which have an energy density of 247Wh/kg and a 4.8Ah/17.3Wh capacity.

The 4680 batteries will have a 50mm instead of a 250mm electrical path.

Tesla is starting to ramp up production of the cells at a pilot facility in California, US.

Unsurprisingly, Musk also announced Tesla aimed to eliminate cobalt in its batteries, moving instead to high nickel cathodes to bring down the cost 15% per $/kWh.

In August, Tesla’s long-term battery partner, Panasonic, announced plans to commercialise a cobalt-free lithium-ion battery within three years.

Musk also announced plans to use “raw metallurgical silicon” in the anode, which could increase EV range by 20% at a cost of $1.20 per anode per kilowatt-hour.

Use of silicon is being investigated by a number of firms. In August, LeydenJar Technologies said it was ready to start producing lithium-ion anodes made from 100% silicon. The spinout from the Dutch applied research institute TNO, claims its technology offered energy density of 1350 Wh/L for more than 100 cycles at a C/2 rate.