Ascend Elements has revealed details of its Hydro-to-Cathode™ technology that recycles critical elements from lithium-ion batteries into new cathode materials

By engineering the composition and microstructure of lithium-ion cathode particles during the direct precursor synthesis phase of its Hydro-to-Cathode process, Ascend Elements says it can deliver custom-made battery materials to precise customer specifications.

The US firm says it can break down a 10-year-old, first-generation EV battery to an aqueous solution containing lithium, nickel and cobalt atoms, and then rearrange those atoms into cathode active materials from NMC 811 to NMCA or any other lithium-ion battery chemistry.

Feedstock can be a mixture of lithium-ion battery types and elemental compositions— from old EVs, laptops, cell phones, scooters, and power tools— with no need to sort batteries into different categories before recycling.

Even gigafactory scrap and waste can be mixed in, says the firm.

Eric Gratz, Ph.D., co-founder and CTO of Ascend Elements, said: “Depending on the intended application, battery manufacturers require cathode active materials with different nickel, cobalt and manganese concentrations. They may need battery material with a specific particle size, crystallinity, or porosity to meet their requirements.

“These adjustments in the elemental composition of the cathode material can make a huge difference in the energy density, safety, power, cycle life and overall performance of batteries.”

He added: “When it comes to recycling used lithium-ion batteries and transforming those critical elements into new cathode material, it doesn’t matter what type of lithium-ion battery is recycled.

“The battery chemistry at the start of the process has no impact on the type of new cathode material we can make from it. If the feedstock is a lithium-ion battery, we can transform it into the latest type of cathode.

“Our technology can customise and engineer cathode active material in many ways – from composition, particle size and distribution to crystallinity, morphology, and porosity – all tailored to specific customer requirements.”

In late 2021, the process was shown to enhance performance of batteries made with recycled materials.

The results were published in peer-reviewed journal Joule.

The results demonstrated that a 1Ah cells—using recycled LiNi1/3Mn1/3Co1/3O2— had the best cycle-life for recycled materials and enabled 4,200 cycles and 11,600 cycles at 80% and 70% capacity retention.

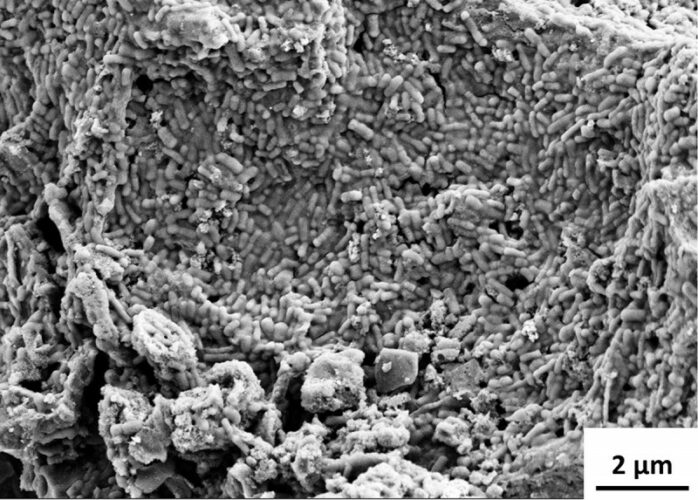

These performance improvements are attributed to the microstructure of the engineered cathode particles.

Modified porosity of cathode particles improves lithium diffusivity, which means lithium ions can travel through the cathode material more easily for higher power capabilities.

The modified pore structure also provides strain relief, allowing expansion and contraction during charging and discharging without damaging the particles in the cathode.

Battery recycling technique

In February, Ascend Elements and Koura, an Orbia business that produces fluoroproducts, partnered to scale the company’s Hydro-to-Anode technology for commercial production.

The firm claims the chemical process recovers 99.9% pure graphite from black mass that has an energy capacity and cycle life on par with virgin battery-grade graphite anode material— although the numbers behind the claim were not released.