Aqua Metals, the Nevada-based lithium battery recycling innovator, has announced production start of the first ever cathode active material (CAM) made from 100% domestically sourced, recycled nickel. According to the company this represents a critical step toward establishing a cleaner, more secure domestic battery supply chain in the U.S.

The U.S. lithium battery industry is projected to surpass 1.2TWh of annual cell production capacity by 2030. Yet much of the necessary raw materials—especially nickel, cobalt, and manganese—are still imported. Establishing a domestic, circular supply chain for these materials is essential to reducing dependence on foreign sources. There are also strategic reasons for establishing a recycling-based supply chain to support the sustainability goals of automakers and battery manufacturers.

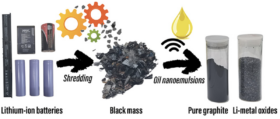

Aqua Metals has developed a proprietary AquaRefining process, to recover high-purity nickel from spent lithium-ion batteries and battery manufacturing scrap. Aqua Metals refined that recycled nickel into battery-grade nickel nitrate. A domestic CAM manufacturing partner then utilised an innovative, low-carbon process to convert the nickel nitrate material into battery-grade CAM. The produced CAM is currently undergoing evaluation by a tier-one lithium battery manufacturer. Initial testing was positive, and the samples are progressing through the validation process.

Company representatives claim that Aqua Metals’ and its U.S.-based partner’s closed-loop production process reduces the carbon footprint of CAM manufacturing by an estimated 87% versus sourcing this critical resource from China.

“This milestone confirms that Aqua Metals’ technology enables the reclamation and reuse of critical minerals entirely within the United States, supporting both energy security and the clean energy economy,” said Steve Cotton, President & CEO of Aqua Metals. “We have demonstrated that a circular supply chain for battery materials is commercially viable today. We are committed to scaling this solution to meet the growing demand for sustainable, high-performance battery components.”