UK-based Altilium Clean Technology has signed a non-binding memorandum of understanding (MOU) to supply recycled graphite to Australian battery materials and technology company Talga Group.

Altilium will supply Talga with up to 16,000 tonnes of recycled graphite over three years, starting next year.

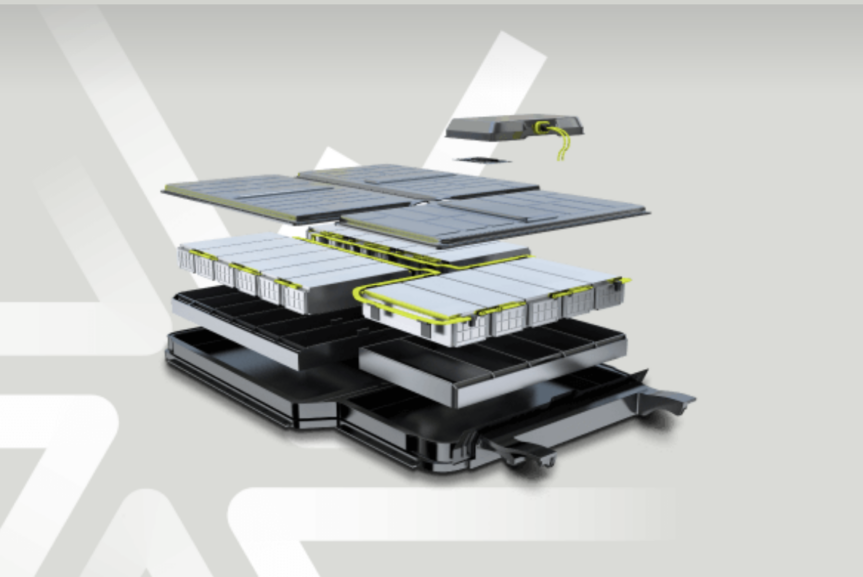

In September 2023, Talga broke ground on its 19,500 tonne per annum graphite anode refinery in Luleå, Sweden. The refinery will produce lithium-ion battery anodes.

The company is also developing a recycled graphite anode product in response to increasing demand for the material. The Talnode-C Recycled Series uses graphite from black mass.

The deal gives Talga a sustainable supply of graphite at a time when natural and synthetic sphereoidised graphite remains subject to export controls by China. More than 90% of the world’s graphite is refined in China.

Recycling battery materials

Altilium reports it can recover 99% of the graphite from end-of-life EV batteries using its EcoAnode process. It also states this recycled material matches the purity and physical characteristics of primary sources.

Last October, the company delivered its Generation 4 EcoAnode graphite samples to a European anode manufacturer.

The company is developing a battery recycling in Teesside, UK, with a capacity to recover 20,000 tonnes of graphite each year.

Last month, Altilium signed a MoU with German tech chemical company Helm to develop a sustainable domestic supply of lithium in the UK.

Altilium is backed by Japanese trading and investment group Marubeni Corporation and SQM Lithium Ventures, part of lithium producer Sociedad Química y Minera de Chile (SQM).