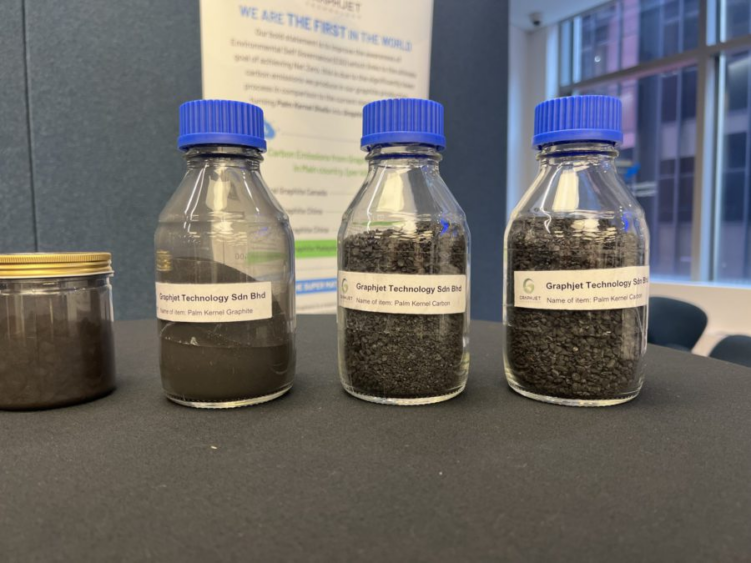

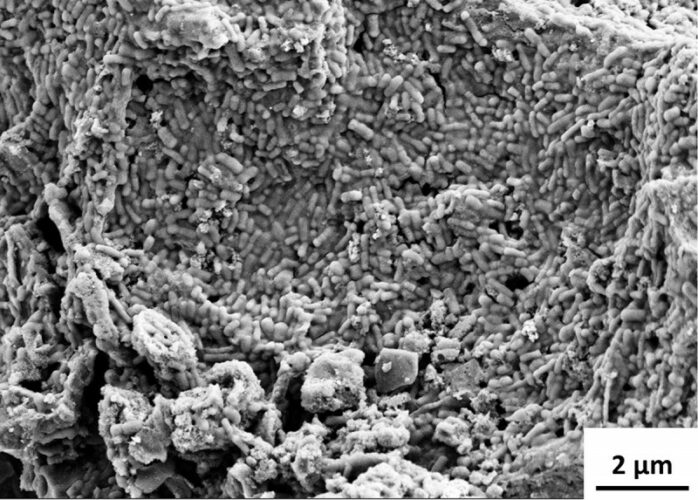

Graphjet Technology, a Malaysian company building a waste-to-graphite and graphene plant in Kuala Lumpur, processing palm kernel shells into hard carbon, outlined plans to build a factory in Nevada to recycle palm kernel.

The US plant is expected to be capable of recycling up to 30,000 tonnes of palm kernel material equivalent into up to 10,000 tonnes of battery-grade, artificial graphite per year.

Graphjet expects to invest $150–$200 million into the facility and is currently evaluating financing.

This production is expected to be able to support the production of enough batteries to power more 100,000 EVs per year, it said.

The Nevada location is close to many US battery and automotive manufacturers, the company said. Aiden Lee, CEO and co-founder of Graphjet said: “As the only pure-play direct agriculture waste-to-graphite technology developer, Graphjet is well positioned to become the leading source of graphite for the US.” He said Nevada would serve as its launch pad into the market. It is in discussions with several players to secure offtake agreements.

Graphjet has created a collaboration network with universities like MIT and the University of Manchester, alongside partnerships with local institutions in Malaysia and Japan.

The Malaysian plant, due to be commissioned in the second quarter of 2024, will ship the hard carbon produced to Nevada. The company is aiming to begin US production in 2026.