Scientists at the National University of Science and Technology “MISIS” (NUST MISIS) in Pakistan have discovered a way to treble the capacity and quintuple the charge/discharge cycles of lithium-ion batteries.

An international team of researchers have synthesised a new nanomaterial that can replace graphite used in current lithium-ion batteries.

The results of the study, published in the Journal of Alloys and Compounds, showed the new anode material provided three times greater capacity than lithium-ion batteries on the market and extended the service life by five times, compared to other promising alternatives to graphite.

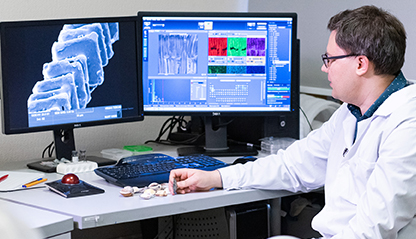

Evgeny Kolesnikov (pictured), an assistant at the Department of Functional Nanosystems and High-Temperature Materials, NUST MISIS, said: “This improvement is achieved due to a synergistic effect with a combination of a special nanostructure and the composition of used elements.”

The novel hollow-structured Cu0.4Zn0.6Fe2O4 porous negative electrode material is synthesized using a one-step spray pyrolysis method, which exhibits excellent rate capability, high cycling stability, and fast charge-discharge performance in lithium-ion batteries.

The scientists said an aqueous solution with ions of special metals is converted into fog with the help of ultrasound, and then water was evaporated at temperatures up to 1,200°C with decomposition of the original metal salts. The result was the extraction of micron or submicron spheres with the correct porosity required to operate in a lithium-ion system.

Evaluation of lithium storage properties reveals that the hollow Cu0.4Zn0.6Fe2O4 nanospheres exhibit high specific capacity of 1122mAh g−1 at a current density of 100mA g−1, excellent rate capabilities up to 1500mA g−1 and long term cycling stabilities at a high rate of 1,000mA g−1. The hollow cavity and porous textures of the Cu0.4Zn0.6Fe2O4 anode are well retained even after 1000 cycles at 1000mA g−1.

The synergistic effect among the different cations, as well as the nano-dimension coupled with a hollow interior and surface porosity of the electrode materials, not only facilitate lithium-ion and electron transportation kinetics but also accommodate large volume expansion.