An academic at Columbia University, US, has developed a trilayer lithium structure that is stable even in ambient air, making the lithium-ion battery both longer lasting and cheaper to manufacture.

The work, which may increase the energy density of lithium batteries by 10-30%, is published in Nano Letters.

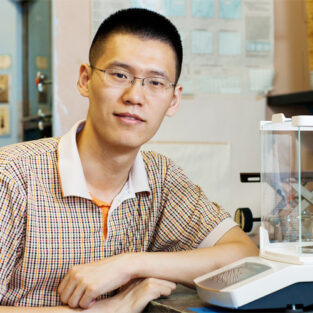

Yuan Yang, assistant professor of materials science and engineering at Columbia Engineering, claimed his new method is capable of preventing 5-20% energy loss in the first cycle of lithium-ion batteries and increases a batteries’ life in portable electronics and electrical vehicles.

Irreversibly, after production of batteries, the first charge of a lithium-ion battery lowers the energy stored in the battery.

The new method reduced the loss capacity in state-of-the-art graphite electrodes from 8% to 0.3%, and in silicon electrodes, from 13% to -15%.

The old school way to tackle the problem is to put certain lithium-rich materials in the electrode, but these materials are not stable in ambient air, because of the moisture.

Yang’s trilayer structure has a layer of the polymer PMMA to prevent lithium from reacting with air and moisture, and then coated the PMMA with such active materials as artificial graphite or silicon nanoparticles. The PMMA layer was then dissolved in the battery electrolyte, thus exposing the lithium to the electrode materials.

He believed that “this could be an attractive advance towards mass production of lithiated battery electrodes”.

His group is now trying to thin the polymer coating so that it will occupy a smaller volume in the lithium battery, and to scale up his technique.