The market for flexible, thin and printed batteries will grow to $500 million within a decade due to the rise of the Internet of Things, wearables and environmental sensors, according to IDTechEx’s report “Flexible, Printed and Thin Film Batteries 2020-2030”.

That’s good news for Blackstone Technology— the German subsidiary of the Swiss firm Blackstone Resources— because it’s just passed crucial milestones for its printed next generation batteries.

It includes patented 3D-printing techniques and research into the mass production of solid-state batteries with greater energy density and cycling.

Last month the company manufactured and successfully tested battery cells with thick, printed electrodes (C/LFP), which enabled the energy density for common cathode chemistries to be increased by around 20%.

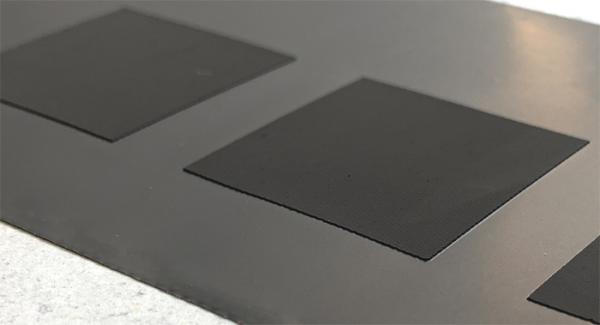

Blackstone’s production technology based on printing batteries covers a range of cell formats using different cathode and anode chemicals

Production eliminates the need for calendaring of electrodes, with necessary porosity adjusted for during printing.

The company says its printing technology represents the cornerstone for the future production of all solid-state batteries, with potential for printing complete battery modules and battery systems at reduced costs.

Holger Gritzka, CEO of Blackstone Technology, said: “The short-term goal is to establish series production and thus prove the suitability for mass production.

“The planning of a first production plant has already begun. The printing of solid-state battery cells is also being tested in parallel. In the medium term, we will print complete battery cells, including housings, at extremely high speed.”