Work is underway to address the role of innovation to accelerate production of critical raw materials for batteries and other applications in Europe.

A new report from systems change company Systemiq and backed by researchers Breakthrough Energy and the Energy Transitions Commission think tank calls for targeted policy support and urges policymakers to:

- accelerate investment in breakthrough technologies that can leapfrog traditional processes

- increase funding

- support innovators in securing offtake agreements

- streamline administrative process

- promote domestic production by targeted trade measures and promoting innovative technologies.

The report focuses on six critical materials facing substantial global supply-demand challenges: copper, nickel, cobalt, lithium, graphite and rare earth elements. Focusing on supply-side innovation, it identifies seven key technologies to sustainably boost supply of these CRMs in the EU and strategic partner countries over the next 10-15 years.

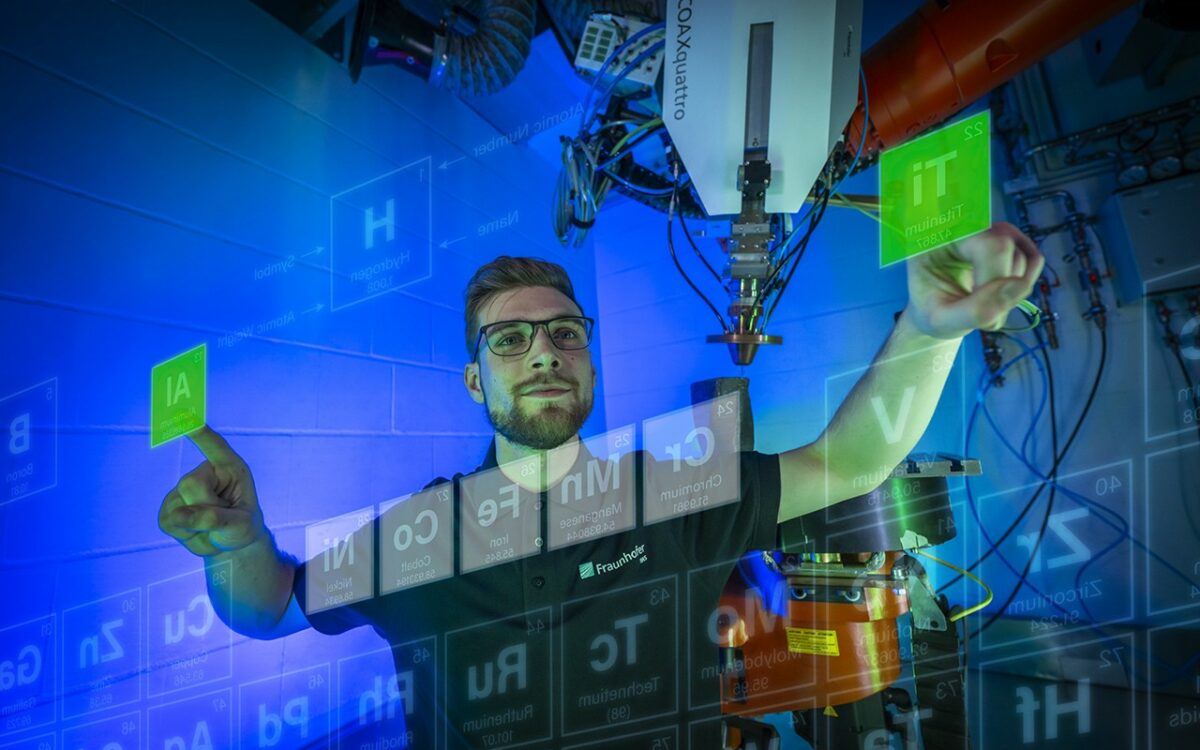

Separately, researchers at Germany’s Fraunhofer Institute for Material and Beam Technology IWS in Dresden announced involvement in a new flagship project to ensure the supply of structurally and functionally secure materials.

As lithium, cobalt, and rare earth elements are often found in only a few countries, dependence and vulnerability of supply chains are increasing, it said. While use of secondary raw materials saves energy and cuts CO2 emissions, contamination can occur during recycling, it noted.

It is caused by foreign substances such as paints, plastics or other metals in the recycled material. This complicates processing and reduces the quality of secondary raw materials. “Another important aspect and a challenge for industries is batch variability,” said Prof. Martina Zimmermann.

The project, called Digital Ecosystem for a Resilient and Sustainable Supply of Functionally Secure Materials aims by end-2027 to find new ways to address raw material shortages and offer adaptation strategies.

Researchers will combine digital models with practical experiments to optimise material properties.

Using additive manufacturing systems, researchers quickly produce samples of the predicted high entropy alloy compositions. The systems mix elemental powders such as iron, chromium and nickel, melt them with a laser, and deposit them onto a sample plate.

Photo: Recording compositions and properties precisely, quickly and cost-effectively to find suitable material combinations. © Martin Förster/SAXONIA Werbeagentur/Fraunhofer IWS