The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University has launched the new CellLab research project to explore the complex relationship between battery manufacturing and performance.

Funded by the state government of North Rhine-Westphalia, the initiative aims to establish a lab that enables reliable and reproducible use of essential measuring instruments.

The new facility will be integrated into PEM’s existing CellFab pilot line – an industrial-style battery cell production setup that spans electrode fabrication, cell assembly and finalisation. CellLab will add cutting-edge analytical tools to this setup, both as in-process modules and post-process systems for quality control. PEM is already gathering extensive data for use in digitalisation research.

“Small and medium-sized industrial companies often lack the resources to set up their own analytics infrastructure for battery production research, which prevents innovations where they would be perfectly possible,” says PEM director, Professor Achim Kampker.

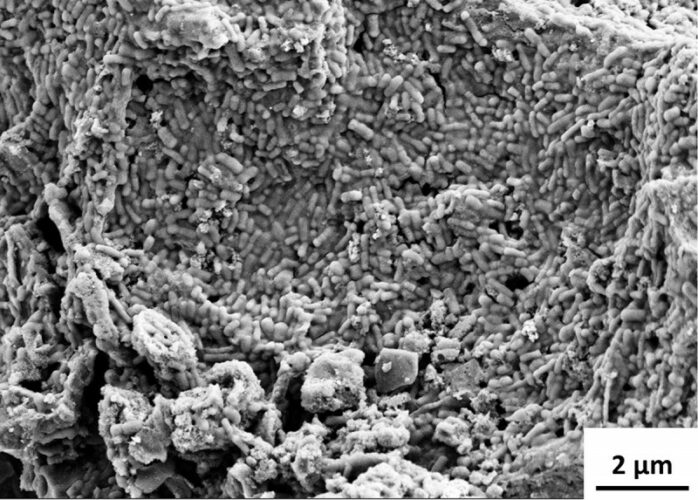

The new tools will help detect characteristics of raw materials, intermediate products, and finished battery cells that were previously hidden from view – free of external environmental interference.

An additional R&D initiative will look into how laboratory data can be used to fine-tune production processes. This is especially relevant for processes like calendering, where production data alone aren’t sufficient to build complete performance models.

“With the help of laboratory data, however, we will be able to make precise predictions, identify sources of error in the product, and optimize quality assurance,” says PEM management member, Professor Heiner Heimes.

By combining real-time data with advanced modelling, the CellLab project is set to significantly boost the efficiency of battery manufacturing.

Image: The CellLab research project has been launched. © PEM RWTH Aachen University | projektelf