Sumitomo Metal Mining has recovered a high-purity nickel-cobalt mixture from used lithium-ion batteries.

The Japan firm has verified that nickel and cobalt recovered from secondary batteries can be reused as a raw material for lithium-ion cathodes.

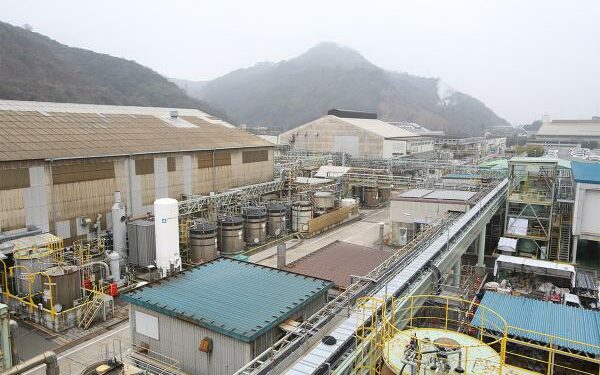

The materials produced at its pilot plant in Niihama City, Ehime Prefecture, performed as well as batteries using existing raw materials derived from natural resources, the company said.

Additionally, Sumitomo was able to produce a soluble slag that enables lithium recovery by pyrometallurgical smelting processes.

The company first developed a recycling process to recover cobalt at the pilot plant using a combination of pyrometallurgical smelting and hydrometallurgical refining processes in 2019.

Sumitomo is now able to recycle copper, nickel, cobalt and lithium from used batteries.

In 2017, the existing smelting and refining processes at the Toyo Smelter & Refinery (Saijo City, Ehime Prefecture) and the Niihama Nickel Refinery (Niihama City, Ehime Prefecture) were used in the implementation of copper and nickel recycling.

A Sumitomo statement read: “The demand for the nickel and cobalt used in EVs is going to expand.

“However, stable supply is a major issue, and there are unbalances in the regions producing these resources and the location of extraction technologies. Demand for recycling of these resources is growing greater than ever.

“If we are able to commercialise this process, which has verified ‘battery to battery’ recycling, we expect to be able to take the domestic sustainable circular economy to the next level and to make contributions to resource recycling in response to global resource depletion.”