Battery recycler Altilium Metals said it selected Teesside for its new facility – the second battery materials processing plant in a week for the region.

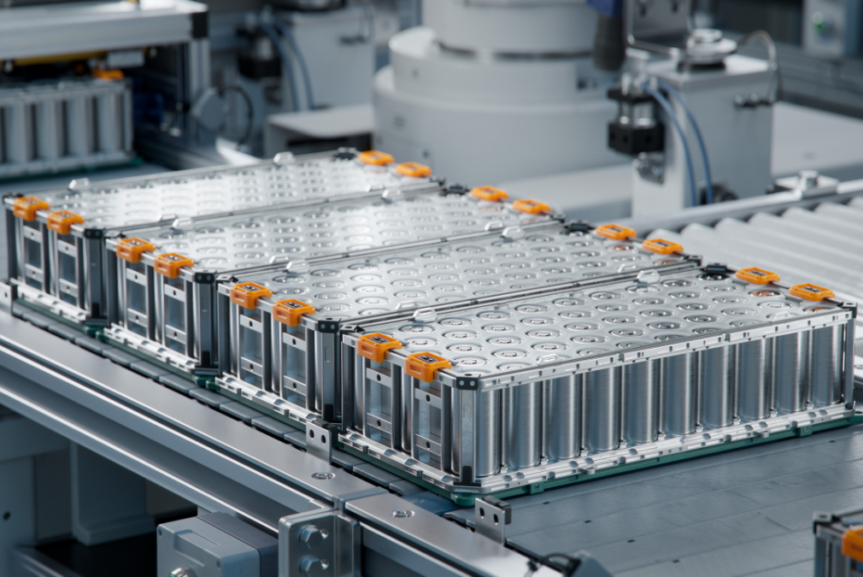

The UK company said it selected Teesside as the preferred location for the largest planned recycling facility in the UK for end-of-life electric vehicle (EV) batteries. The mega-scale recycling plant would be able to recycle battery waste from 150,000 EVs a year, the company said.

The plant will be designed by Canadian engineering company Hatch. The final, exact location for the Teesside site is expected to be determined early in 2023. It said it has secured over £3 million in Government Innovation awards to scale up its proprietary recycling technology.

Tees Valley Mayor Ben Houchen said: “We’re seeing a lot of activity in EV innovation here, with other plans for lithium plants for battery production moving on swiftly.” Battery start-up Britishvolt is located 50 miles north.

Altilium said its ambition is to have two sites operational by 2030. It operates a SX-EW hydrometallurgical plant on the largest copper mine waste resource in eastern Europe, which is currently being retrofitted to recycle battery waste from 24,000 EVs.

At its newly opened EV Battery Recycling Technology Centre in the UK, its scale-up processing line will provide the company with data to make informed decisions on materials handling, scalability and product quality at the planned Teesside mega-scale recycling plant.

On Monday, battery recycler Green Lithium announced plans to build the UK’s first large-scale lithium refinery at nearby PD Ports, also on Teesside.

Spokesperson for Tees Valley Combined Authority, Alex Metcalfe, said the Altilium announcement was a “happy coincidence”. The two projects are not connected, he said.