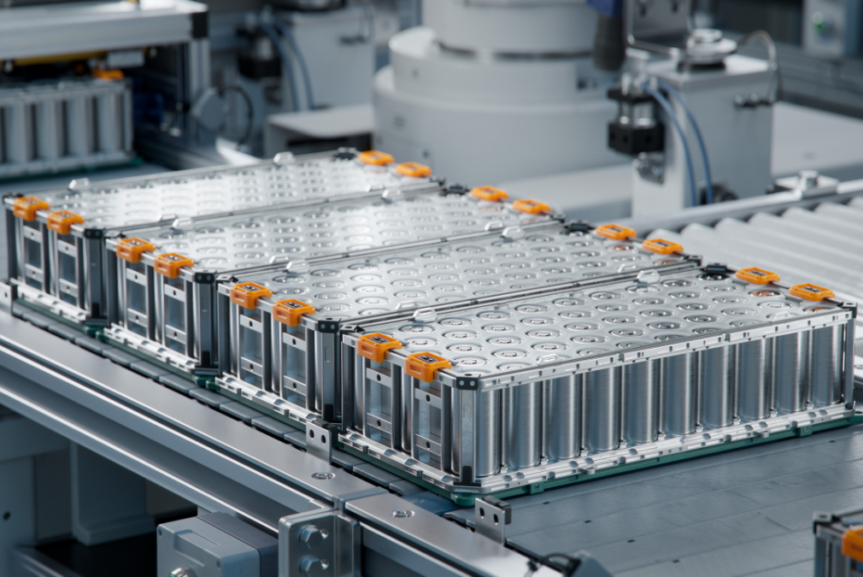

EV maker Tesla is to invest up to $6bn in a US ‘Gigafactory’ to produce 35 GWh/50 GWh of 18650 lithium-ion cells/packs a year.

Tesla wants to manufacture its own cells and battery packs to lower costs by achieving greater economies of scale and minimising costs via reduced overheads, guarantee of supply, reducing the supply chain and co-locating processes.

In a statement, Tesla said construction of the plant would begin this year, with production beginning in 2017. The location of the plant is still to be decided, although California has been ruled out as a location; Tesla said it will choose from one of four states: Nevada, New Mexico, Arizona and Texas.

The EV maker believes it can drive down the cost per kWh by more than 30% by the end of the factory’s first year of full capacity production. When the location has been decided, construction will be completed by the end of 2015 with equipment being installed in 2016 and production to begin from 2017, reaching full capacity – enough cells for 500,000 cars a year – by 2020.

Tesla said its “manufacturing partners” will help build and finance the factory, assumed to be Panasonic, which currently supplies 18650 cells for the Model S. Rumoured potential partners in the venture include Samsung and Apple.

Panasonic is inviting other Japanese material suppliers to invest in Tesla’s battery plant. Investment is expected to be in the region of $979m.

To help finance the investment, Tesla also announced a $1.6 billion convertible debt offering.