Car maker Toyota announced an agreement on Thursday to work with Idemitsu Kosan Co on mass production of all-solid-state batteries. They will develop mass production technology of solid electrolytes, improve productivity and establish a supply chain.

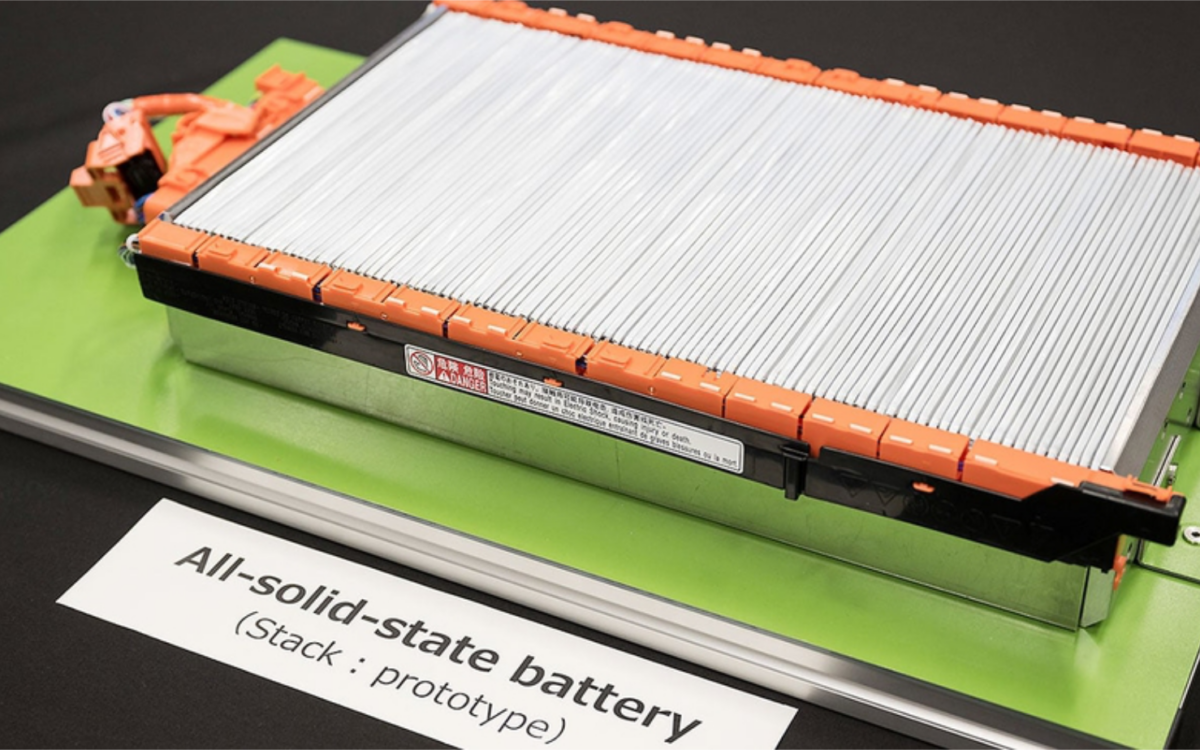

They plan successful commercialisation of all-solid-state batteries in 2027–28 followed by full-scale mass production. In June, Toyota previously outlined plans for new solid-state batteries with a cruising range of 1,000 km.

Idemitsu has been working on research and development on elemental technologies for solid-state batteries since 2001. Toyota started in 2006, it said.

The collaboration focuses on sulfide solid electrolytes, which Toyota said are seen as a promising material to achieve high capacity and output for battery electric vehicles (BEVs). Sulfide solid electrolytes are soft and stick to other materials, making them suitable for battery mass production.

The companies will use an Idemitsu pilot facility.

At a presentation on Thursday, Koji Sato, President and CEO of Toyota, said as solid-state batteries are smaller and more powerful, they will enable battery EVs to meet a diverse range of needs. They go from sports cars, which require high-power performance, to commercial vehicles, which require frequent quick recharging.

“On the other hand, the biggest challenge is durability,” he said. A longstanding technical issue is that repeatedly charging and discharging the battery causes cracks between the cathodes and anodes and the solid electrolytes, degrading battery performance.

Toyota has worked with Idemitsu, which has come up with a highly flexible, adhesive, and crack-resistant solid electrolyte. “Through repeated trial and error and by combining the material technologies of both companies, we have been able to develop a crack-resistant material that demonstrates high performance,” he said.

The two will combine materials development and battery mass production technology in an effort to make the solid-state batteries.