AM Batteries, the Massachusetts-based dry-electrode specialist, and Tokyo-based Zeon Corporation have formed a new partnership to develop dry battery electrode manufacturing.

As part of this deal, Zeon worked closely with AM Batteries to support the commercialisation of the company’s electrode manufacturing solution for lithium-ion batteries, creating a more energy efficient process. AM Batteries claims energy savings can reach 40% compared to the conventional methods starting with slurry mixing and including two drying steps.

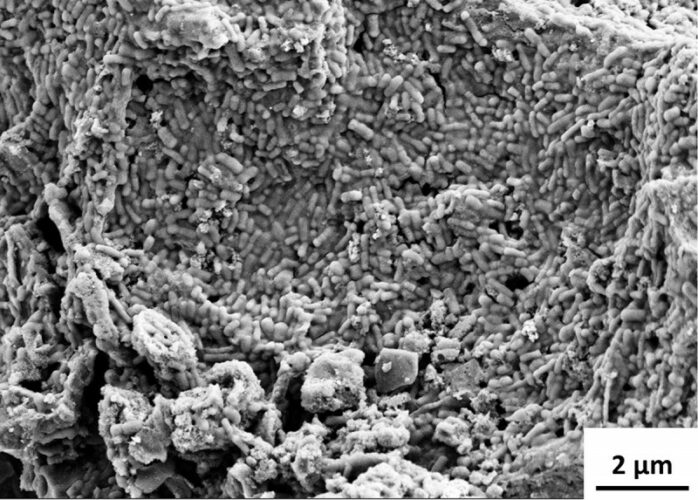

AM Batteries has developed a ‘powder to electrode’ method, which cuts the drying and solvent recovery steps. In order to eliminate the need for the wet-coating process, it is building a system suited to the need to develop batteries through the dry process at every level of the supply chain. By working with Zeon, AM Batteries said it is optimising the dry electrode performance with a novel binder at a lower cost.

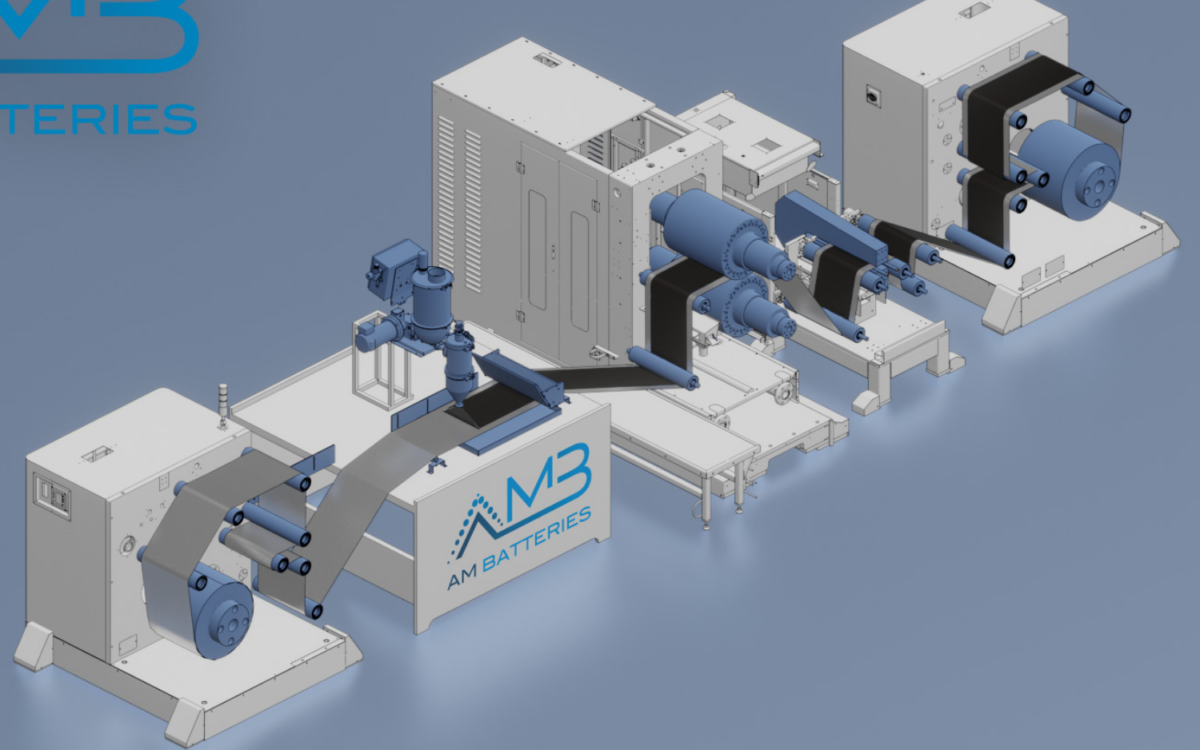

The AM process includes dry mixing of cathode/anode active powder with polymer binder and conductive additive, followed by application of dry mixed electrode powder onto a substrate via an electrostatic spray deposition system. The dry electrode material is then finalised through mechanical compression and binding of particles to the substrate via a hot calendaring system.

“AM Batteries has been at the forefront of dry battery electrode manufacturing and is creating a more energy efficient, low cost, and lower carbon footprint method for electrode manufacturing,” said Lie Shi, CEO of AM Batteries.

Zeon has previously invested in AM Batteries in 2022 and 2023, and in other US companies through its venture capital arm Zeon Ventures.