Vehicle OEM the Volkswagen Group has announced it will build 240GWh of lithium-ion manufacturing capacity in Europe by 2030.

The plans are part of the German company’s technology roadmap for batteries and charging up to 2030, which it announced during its first “Power Day” on 15 March.

The company plans to build six gigafactories by 2030 to make lithium-ion cells, including the company’s ‘unified cell’.

The first plant, in partnership with Northvolt, will produce up to 40GWh of VW’s “premium” cells in Sweden.

The second, in Salzgitter, Germany, will be run by VW and make up to 40GWh of its high manganese lithium-ion cells from 2025. The involvement of technology partners and suppliers is being considered.

Potential sites and partners are being considered for the other four factories.

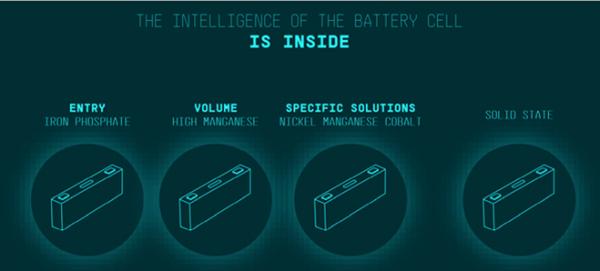

The unified cell will include four chemistries, depending on application: iron phosphate (entry chemistry for cheaper EV models), high manganese (high volume), nickel-manganese-cobalt (for long-range high-performance EVS) and solid state.

A variant of the new cell will be installed in up to 80% of all electric vehicles in the Group in 2030.

The company expects significant cost benefits by making the prismatic unified cell, which will offer VW the best conditions for the transition to the solid-state cell due to be launched in 2023.

A VW spokesman told BEST: “Unified cell refers to a cell format that will be standardised and which will be able to accommodate several cell chemistries, which in turn will define cell properties.

“Together with our suppliers we will develop the unified cell as a prismatic cell format.

“However, we will also have other cell formats; for 20% of the expected volume, other cell formats are planned.”

The goal of the roadmap is to reduce the complexity and cost of the battery and guarantee security of supply of battery cells beyond 2025.

The Group’s technology roadmap will also focus on integrating more steps along the value chain through to industrial recycling.