German vehicle OEM conglomerate Daimler is planning to invest in nickel-cobalt-manganese battery maker Farasis Energy’s IPO, according to reports.

The announcement, reported by The New York Times, comes as the electric vehicle battery maker Farasis received regulatory approval to raise around 3.4 billion yuan ($479 million) in an initial public offering on China’s Nasdaq-like STAR board.

However, a Daimler spokesperson told BEST “we do not comment on speculations” when asked if the reports were true.

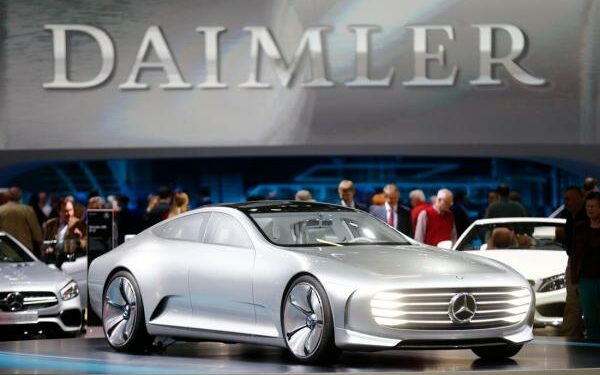

Although it is not clear how much Daimler will invest, the German OEM’s subsidary Mercedes-Benz is investing more than €1billion ($1 billion) to establish a global battery production network of nine battery factories at seven locations in Europe, North America and Asia.

This despite Daimler posting a profit of €2.7billion ($3billion) for 2019— almost €5billion ($5.5 billion) less than the previous year’s performance.

The spokesperson told BEST Mercedes-Benz EQC wwas working with a NMC mixture becuase of the chemsitry’s longevity of the cells, safety and allowed the “maximum flexibility in our battery electric architecture” while preparing the way for next generations of battery electric vehicles.

They said: “Lithium-ion technology is the most efficient battery technology available, and still shows plenty of potential for the future. But we are consistently working on optimisations and alternatives beyond lithium-ion— not least regarding energy density and charging times, but sustainability as well.

“Mercedes-Benz is working to optimise the material composition of batteries with the aim to significantly reduce the percentage of critical resources such as cobalt. In addition, the company is already researching future cell technologies that are fully recyclable and could completely eliminate the need for potentially critical materials.”

To date, Mercedes has been producing drivetrain batteries for electric and electrified vehicles since 2012, through its subsidiary Accumotive in Kamenz, Saxony. Accumotive opened a second plant in 2018 for hybrid, plug-in hybrid and purely electric vehicles. The battery systems consist of 384 cells.

The firm has a battery production facility in Bangkok, Thailand, with its joint venture partner Thonburi Automotive Assembly Plant, which started operations in 2019.

It set up a battery production facility with state-owned BAIC at an existing plant in the Yizhuang Industrial Park in Beijing, China. The pair entered into a development partnership to establish Beijing’s first second-life energy storage system facility last year.

There is also a battery factory in Jawor, Poland, which is due to start production this year; battery factories being built at the Brühl and Hedelfingen locations in Germany; a battery factory is being built near an existing plant in Tuscaloosa, US; and a new battery factory will also be built at the company’s Sindelfingen plant in Germany.

Jörg Burzer, member of the board of management of Mercedes-Benz AG, production and supply chain management, said: “Our goal is an organic global network in which production capacities can be flexibly shifted between plants around the world.”