The lead-acid battery industry likes to push the PR line that it is one of the most recycled products on the planet at around 96%— but the battery’s reusable material currently sits at around 65%.

That was until UK headquartered Eco-Bat developed a 12V flooded battery made from 92% recycled materials, including the lead and acid electrolyte.

Once issues with the battery’s handle (it doesn’t meet European regulations about strength) is rectified that percentage could reach as high as 95%.

The industry milestone is about to be market tested in Europe and displayed at key battery conferences this year, before a decision is made whether to bring it to mass market.

The 100ah and 75ah replacement batteries are designed to reach performance criteria for high-end cars.

Tim Ellis, from RSR Technologies, told BBB: “This is an outstanding demonstration of lead-acid recyclability in supporting a closed loop economy. Nobody is designing a battery with the closed loop market in mind.

“Most lead-acid batteries have recycled material, we attempted to drive the recycle content as high as possible in this exercise.”

The battery uses recycled sulfuric acidwhich accounts for around 25% of the weight of a lead-acid battery.

The battery more than exceeds the EU Battery Directives metrics which asks for 50% of recycled material, which other chemistries have not come anywhere near, said Ellis.

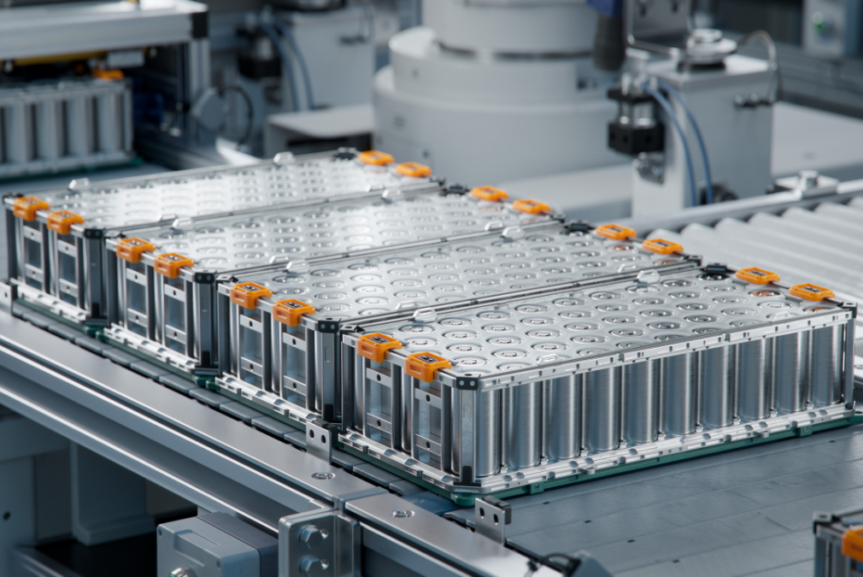

This closed loop market is set to become a key area of discussion in the next decade as lithium-ion batteries (especially from electric vehicles) reach their end of life.”

Current legislation in Europe has the appearance of a drive to outlaw lead-acid in favour of lithium-ion.

However, recycling lithium-ion still does not make any economic sense because they only contain a small amount (in weight percentage) of lithium carbonate, and recycled lithium currently costs up to five times as much as its primary equivalent.