Italian engineering company Engitec Technologies has finalised its first contract for a new kind of lead-acid battery recycling plant in west Africa, which it hopes will open doors to other projects in sub-Saharan Africa.

Engitec Area Manager Daniele Silla told BEST the project has been slightly complicated by administrative formalities but plans are now on track with the client, Mabani ZM, he said.

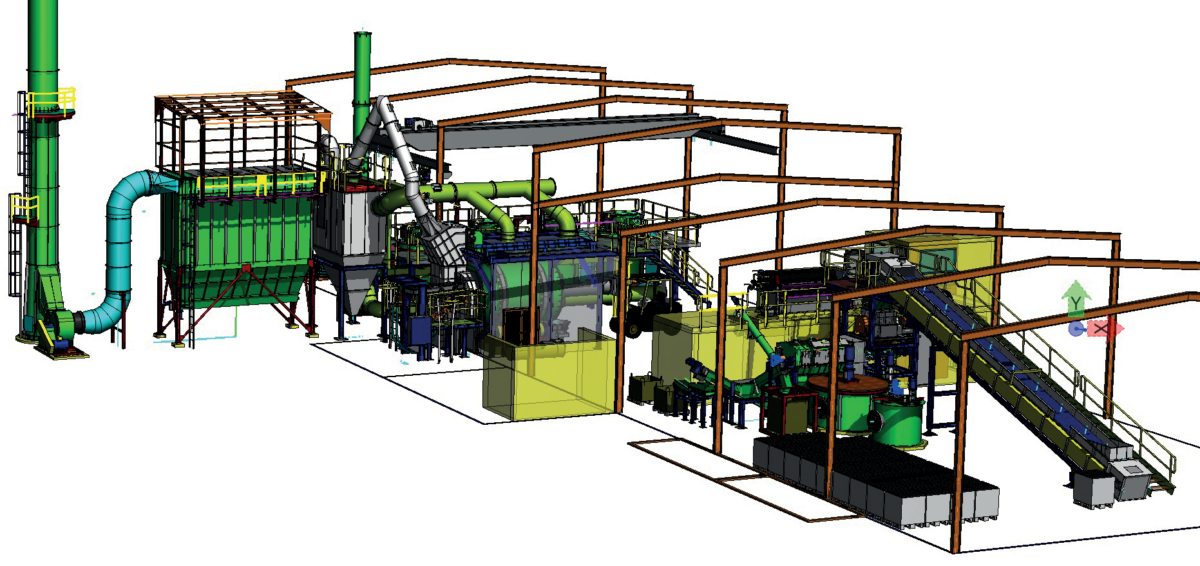

The equipment is called CX Smart and is designed for small-scale production, where used lead battery supplies are limited. A fully automated system involving large capex is not always wanted in developing countries, he said.

The plant includes the foundry refinery, ingot caster and pollution control system. It can process up to 1.5 tonnes per hour and 12,000 tonnes per year of scrap lead batteries. It can cast four tonnes of ingots per hour, collect and filter electrolyte, separate components, filter lead paste and smelt lead. It has scrubber filtration and a 1.5 cubic metre rotary furnace.

This CX Smart plant is much smaller than Engitec’s biggest CX 50tph breaker, which can handle 50 tonnes per hour.

Silla said: “We design and manufacture the plants, and then we ship the equipment to the client. The client is normally having its own erection company, and we are there to assist them during erection, training, cold and hot tests up to the demonstration of performance parameters.

“So we provide technical assistance, we have our site specialists for mechanical, electrical and software processes. And once the plant is erected, perfectly erected and checked, then we pass to the last two phases – that is the commissioning of the plant and the training of the operators.”

He said Engitec expects to ship the plant in the first quarter of 2025 and aims to have it operative from around the middle of 2025. It will manufacture and assemble the plant in its Italian workshops.

Financial details have not been disclosed, but Silla said this is a first move by this industrial company into lead battery recycling.

Commercial and marketing director Carmelo Maria Brocato said after-sales service to customers in developing countries where infrastructure is incomplete is very important. “Our goal for these small plants for regional applications sold to countries in Africa or somewhere like that is to provide a continuous service, either by our presence or in remote mode, to these people how to write the GMPS good manufacturing practice, how to respect, how to implement, how to manage the laboratory results, how to link laboratory failure to the machine. So we foresee for the next few next years to come, let’s say a continuous support.”

Silla said the customer has ambitious plans but will take things a step at a time, starting with this plant. He said Ivory Coast is well placed to develop lead battery recycling due to its stability and coastal location.

Brocato added: “This project is very important for Engitec because we always go with the demographic dynamics and the study of the local situation. Africa in 2040 will have two billion people. India in 2040 will have 1.9 billion people…So, for us, this first project in Black Africa is extremely important because we are quite sure that in the next five or six years, we will have more concrete opportunities for projects in this part of the world.”

Image: Complete Engitec CX Smart Plant. Engitec