Battery separator manufacturer Entek is investing £10m ($17m) to develop its next generation lead-acid separator materials for automotive batteries at its UK manufacturing plant.

The company is keeping the new separator, which will be formally unveiled at the 14th European Lead Battery Conference in Edinburgh this September, under wraps. The first phase of the investment includes £2.5m of new machinery installed at its site near the city of Newcastle, with more to follow in the coming 18 months.

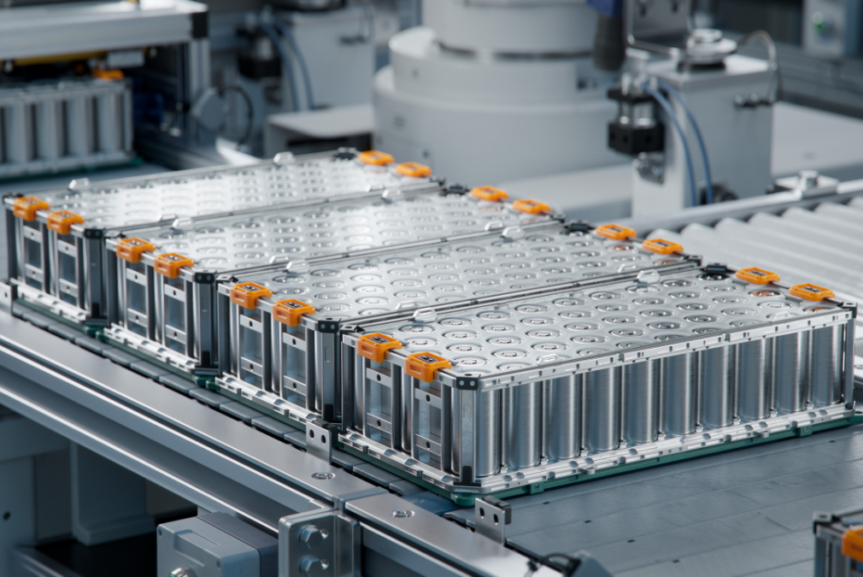

Two new production lines were installed at the plant four years ago to continually mix and extrude materials into continuous polyethylene sheets, which are then subjected to specialised process treatments to become separators.

The US-owned company has manufacturing sites around the globe including the plant in Killingworth in the north of England.

Meanwhile, Entek has rebranded, bringing all three of its operating divisions under a common-look logo-wise and with a single Web presence.

The company’s new brand is a forward-leaning “e” in dark orange next to the word “ENTEK” in dark brown. It replaces a red, white and blue “ENTEK” enclosed in a rectangle that had been used for many years.

David Trueba, Entek’s VP for sales & marketing, told BEST the rebranding brings together the Oregon firm’s manufacturing of membrane battery separator materials for lead-acid and lithium-ion batteries; design and manufacture of extrusion machinery; as well as its own proprietary product units under one umbrella. “Even our business cards looked like we were from different organisations – this is a big, welcome change,” said Trueba.