UK engineering firm Tecman said it has developed a process to enable high volume production of framed battery anti-thermal propagation (ATP) pads. The product was launched at this week’s Battery Cells and Systems Expo in England.

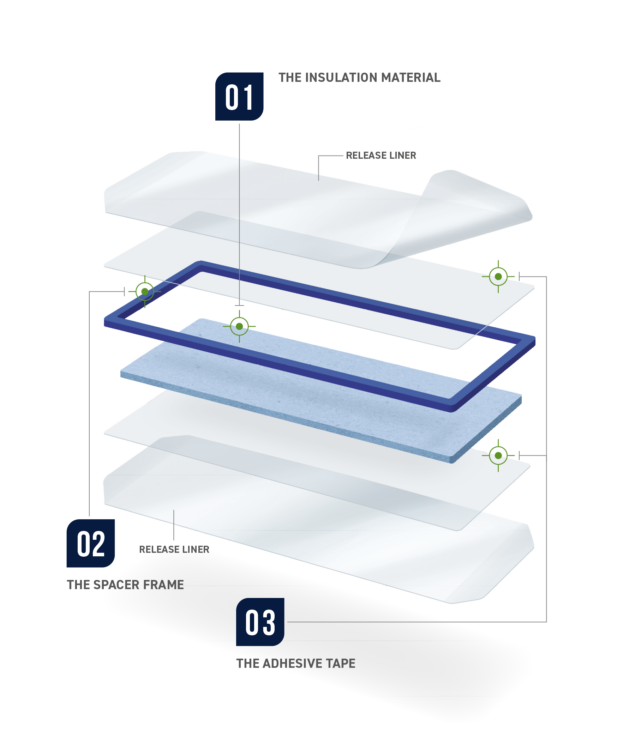

It said it spent 18 months developing and patenting the single continuous production process that enables the company to manufacture framed ATP pads. They are a type of advanced cell barrier including a physical built-in spacer around the insulation pad.

The company said the pad provides optimal space between battery cells and helps to prevent thermal propagation by allowing the cells space to expand and contract, and by providing a degree of mechanical resistance to the cell wall.

Manufacture of this kind of cell barrier with built-in spacers has been complex because of the multiple components required. Tecman claims its process eliminates the need for third-party pre-conversion and cuts costs with manufacturing speed of 120 parts per minute.

The customisable pads will suit multiple prismatic and pouch cell solutions, it said. Kevin Porter, Technical Director at Tecman, said: “Framed ATP Pads have been so complicated to manufacture that it has prohibited the development of this design to date, so we are delighted to be the first to bring this innovation to market.”